The agricultural industry stands at the precipice of a technological revolution that promises to transform farming practices fundamentally through the integration of artificial intelligence and autonomous robotics. Leading this transformation are industry giants John Deere and Case IH, both pioneering groundbreaking autonomous tractor technologies that represent the future of precision agriculture. These sophisticated machines combine advanced AI algorithms, GPS navigation systems, sensor technologies, and machine learning capabilities to create farming solutions that optimize productivity while reducing operational costs and environmental impact.

Discover the latest AI trends in agricultural technology to understand how artificial intelligence is reshaping farming practices and revolutionizing food production systems worldwide. The emergence of autonomous agricultural equipment represents more than technological advancement; it signifies a fundamental shift toward sustainable, efficient, and data-driven farming methodologies that address the growing global demand for food production while minimizing resource consumption and environmental degradation.

The Evolution of Agricultural Automation

The journey toward fully autonomous agricultural equipment has been decades in the making, evolving from simple mechanization to sophisticated AI-driven systems capable of making complex decisions in real-time. John Deere and Case IH have emerged as frontrunners in this technological race, each developing distinct approaches to autonomous farming that reflect their unique engineering philosophies and market positioning strategies. The evolution from traditional farming equipment to intelligent, self-operating machines represents one of the most significant technological leaps in agricultural history.

Modern autonomous tractors incorporate multiple layers of artificial intelligence, including computer vision systems that can identify crop types, detect weeds, assess soil conditions, and navigate complex field environments without human intervention. These systems process vast amounts of data from multiple sensors, satellite imagery, weather stations, and historical field performance records to make informed decisions about planting patterns, fertilizer application, irrigation scheduling, and harvesting optimization.

The technological sophistication of these machines extends beyond basic navigation and operation to include predictive analytics capabilities that can forecast crop yields, identify potential disease outbreaks, optimize resource allocation, and recommend strategic farming decisions based on comprehensive data analysis. This level of intelligence transforms traditional farming from a reactive practice to a proactive, scientifically-driven approach that maximizes both productivity and sustainability.

John Deere’s Autonomous Technology Leadership

John Deere has established itself as a pioneering force in autonomous agricultural technology through its comprehensive approach to smart farming solutions that integrate seamlessly with existing farm management systems. The company’s autonomous tractors represent the culmination of decades of research and development in GPS guidance systems, machine learning algorithms, and precision agriculture technologies that have revolutionized farming practices across diverse agricultural environments.

Experience advanced AI capabilities with Claude to understand how sophisticated artificial intelligence systems like those powering John Deere’s autonomous tractors process complex agricultural data and make real-time farming decisions. The company’s flagship autonomous tractor systems incorporate advanced computer vision technology that enables precise identification of crop rows, detection of obstacles, and real-time adjustment of operational parameters based on changing field conditions.

John Deere’s approach to autonomous technology emphasizes seamless integration with the company’s existing ecosystem of precision agriculture tools, including their Operations Center platform that provides comprehensive farm management capabilities through cloud-based data analytics and remote monitoring systems. This integrated approach allows farmers to manage multiple autonomous machines simultaneously while maintaining complete oversight of field operations through intuitive digital interfaces that provide real-time operational status, performance metrics, and predictive maintenance alerts.

The company’s autonomous tractors feature sophisticated sensor arrays that include LiDAR systems, stereo cameras, radar units, and GPS receivers that work in conjunction to create detailed three-dimensional maps of field environments. These sensor systems enable the tractors to operate safely and efficiently in various weather conditions, navigate around obstacles, and maintain precise positioning accuracy even in challenging terrain or low-visibility conditions.

Case IH’s Innovative Autonomous Solutions

Case IH has distinguished itself in the autonomous agriculture market through its focus on developing robust, reliable systems that prioritize operational efficiency and farmer-friendly interfaces while maintaining the highest standards of safety and precision. The company’s autonomous tractor technology reflects a deep understanding of practical farming challenges and the need for equipment that can operate reliably in diverse agricultural environments while delivering consistent performance across different crop types and field conditions.

The Case IH approach to autonomous technology emphasizes modular design principles that allow farmers to upgrade existing equipment with autonomous capabilities rather than requiring complete equipment replacement. This strategy makes autonomous technology more accessible to farmers with varying budget constraints while ensuring compatibility with existing farm infrastructure and operational workflows. The company’s autonomous systems can be integrated with various implement types, enabling versatile applications across different farming operations.

Case IH’s autonomous tractors incorporate advanced path planning algorithms that optimize field coverage patterns to minimize soil compaction, reduce fuel consumption, and maximize operational efficiency. These systems can automatically adjust working patterns based on field characteristics, crop requirements, and environmental conditions while maintaining precise application rates for seeds, fertilizers, and other agricultural inputs.

The company’s commitment to safety in autonomous operations is evident in their multi-layered safety systems that include redundant sensor networks, emergency stop protocols, and continuous monitoring capabilities that ensure safe operation even in unexpected situations. These safety features provide farmers with confidence in autonomous technology while meeting stringent agricultural safety standards and regulatory requirements.

Technological Architecture and AI Implementation

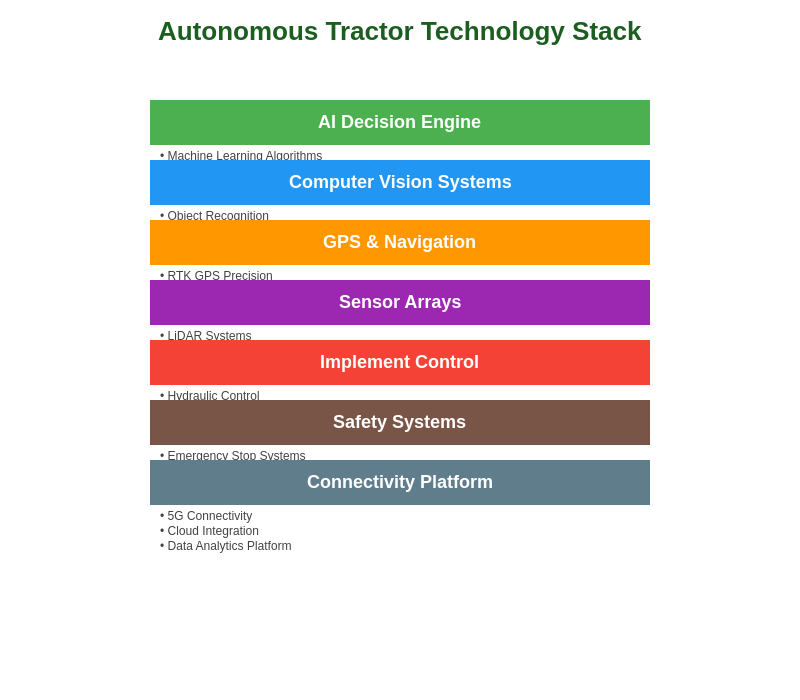

The technological foundations of both John Deere and Case IH autonomous tractors rely on sophisticated artificial intelligence architectures that process massive amounts of data from multiple sources to enable intelligent decision-making and autonomous operation. These systems incorporate machine learning algorithms trained on extensive datasets of agricultural operations, enabling them to recognize patterns, predict outcomes, and optimize performance based on accumulated experience and real-time environmental data.

The AI systems powering these autonomous tractors utilize deep learning neural networks that can process visual data from camera systems to identify crop types, assess plant health, detect pest infestations, and recognize weed species for targeted treatment applications. This computer vision capability enables precision agriculture practices that were previously impossible with traditional farming equipment, allowing for selective treatment of specific areas within fields rather than blanket application of inputs across entire fields.

The sophisticated technology architecture underlying modern autonomous tractors demonstrates the complexity and integration required to achieve reliable autonomous operation in agricultural environments. Each technological layer builds upon the others to create comprehensive systems capable of independent decision-making and precise operational control.

Explore comprehensive AI research capabilities with Perplexity to delve deeper into the machine learning algorithms and data processing methodologies that enable autonomous agricultural equipment to make complex farming decisions in real-time. The integration of edge computing capabilities in these systems allows for real-time data processing and decision-making without relying on constant connectivity to cloud-based services, ensuring reliable operation even in areas with limited internet connectivity.

Both manufacturers have invested heavily in developing robust data management platforms that can handle the enormous volumes of information generated by autonomous farming operations. These platforms integrate data from multiple sources, including weather stations, soil sensors, satellite imagery, and historical field performance records, to provide comprehensive insights that inform both autonomous operations and strategic farming decisions.

Performance Comparison and Operational Capabilities

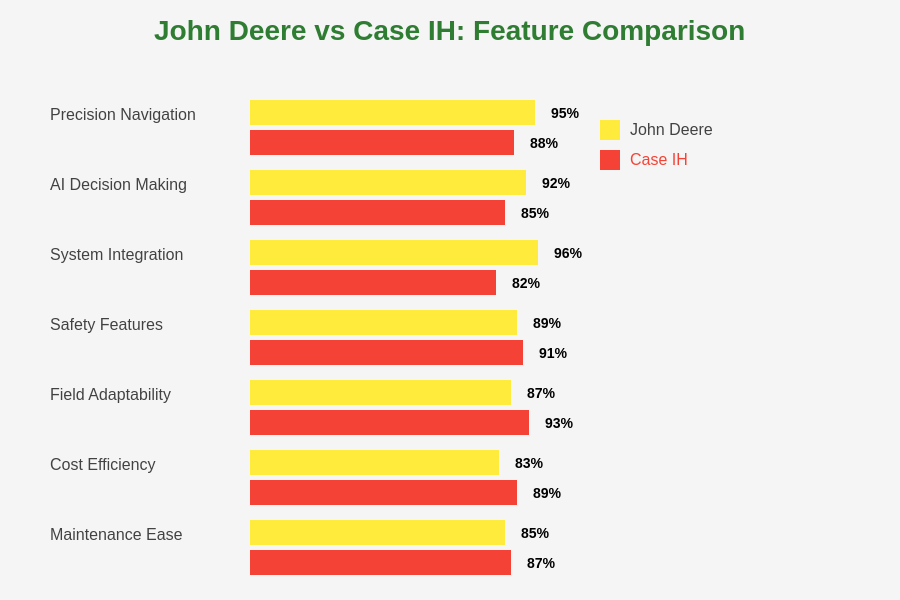

When comparing the operational capabilities of John Deere and Case IH autonomous tractors, several key performance metrics emerge that distinguish these systems in terms of efficiency, precision, and adaptability to different farming environments. Both manufacturers have achieved remarkable levels of operational autonomy, but their approaches to achieving these capabilities reflect different engineering philosophies and target market considerations.

John Deere’s autonomous systems excel in precision positioning and integration with comprehensive farm management ecosystems, offering farmers detailed control over every aspect of autonomous operations through sophisticated software interfaces. The company’s systems demonstrate exceptional accuracy in field navigation and implement control, with positioning precision measured in centimeters rather than meters, enabling optimal seed placement, fertilizer application, and cultivation operations.

Case IH’s autonomous technology distinguishes itself through robust performance in challenging field conditions and exceptional reliability during extended autonomous operations. The company’s systems are designed to handle diverse terrain conditions, varying crop types, and unpredictable weather situations while maintaining consistent operational performance and minimal downtime for maintenance or technical issues.

Both systems demonstrate impressive fuel efficiency improvements compared to traditional farming operations, with autonomous tractors optimizing engine performance, travel patterns, and implement operation to minimize energy consumption while maximizing productivity. These efficiency gains translate directly into reduced operational costs and improved environmental sustainability for farming operations of all sizes.

The comprehensive feature analysis reveals distinct strengths and capabilities between John Deere and Case IH autonomous tractor systems, with each manufacturer excelling in different aspects of autonomous agricultural technology. This comparison helps farmers evaluate which system best aligns with their specific operational requirements and farming objectives.

Safety Systems and Regulatory Compliance

The development of autonomous agricultural equipment has required both John Deere and Case IH to implement comprehensive safety systems that exceed traditional agricultural equipment standards while addressing the unique challenges associated with unmanned vehicle operations in agricultural environments. These safety systems represent critical differentiators between manufacturers and essential considerations for farmers evaluating autonomous technology adoption.

John Deere’s safety architecture incorporates multiple redundant systems that continuously monitor equipment operation, environmental conditions, and potential safety hazards while maintaining constant communication with farm management systems. The company’s autonomous tractors feature emergency stop capabilities that can be activated remotely or automatically in response to detected safety risks, ensuring immediate cessation of operations when necessary.

Case IH has implemented similar safety protocols while emphasizing simplicity and reliability in safety system operation. The company’s approach focuses on intuitive safety controls that enable farm operators to quickly understand and respond to safety situations while maintaining confidence in autonomous system operation during normal farming activities.

Both manufacturers have worked closely with regulatory agencies to ensure their autonomous systems comply with evolving safety standards and operational regulations for unmanned agricultural vehicles. This regulatory compliance is essential for widespread adoption of autonomous technology and provides farmers with assurance that their equipment meets legal requirements for autonomous operation.

Economic Impact and Return on Investment

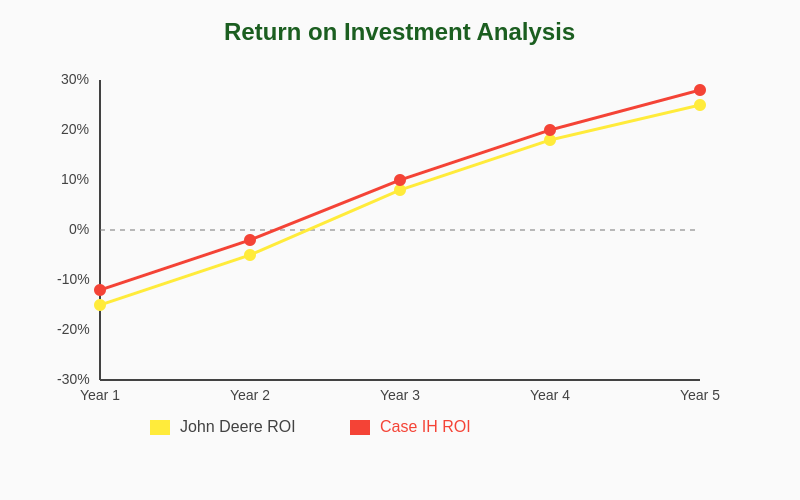

The economic implications of adopting autonomous tractor technology extend far beyond the initial equipment investment, encompassing operational cost savings, productivity improvements, and long-term strategic advantages that can significantly impact farm profitability and sustainability. Both John Deere and Case IH autonomous systems offer compelling economic value propositions, though the specific benefits may vary depending on farm size, crop types, and operational characteristics.

Autonomous tractors enable significant labor cost savings by reducing the need for skilled operators during routine field operations while allowing existing farm personnel to focus on higher-value activities such as crop monitoring, equipment maintenance, and strategic planning. This optimization of human resources can result in substantial cost savings for large-scale farming operations while improving job satisfaction and safety for farm workers.

The precision capabilities of autonomous systems contribute to improved input efficiency, reducing waste in seed, fertilizer, and chemical applications while optimizing crop yields through more accurate planting patterns and cultivation practices. These efficiency improvements can result in measurable cost savings and yield improvements that accumulate over multiple growing seasons to provide substantial return on investment.

Both manufacturers offer comprehensive financing and leasing options that make autonomous technology accessible to farms of varying sizes while providing flexible payment structures that align with agricultural cash flow patterns. These financing options often include performance guarantees and service packages that further enhance the economic attractiveness of autonomous technology adoption.

The return on investment trajectory for autonomous tractor technology demonstrates the long-term financial benefits of adopting these advanced agricultural systems. While initial investment costs create negative returns in early years, the cumulative efficiency gains and operational savings generate substantial positive returns over the equipment lifecycle.

Environmental Sustainability and Precision Agriculture

The environmental benefits of autonomous agricultural technology represent one of the most compelling arguments for widespread adoption of these systems, as they enable farming practices that minimize environmental impact while maintaining or improving agricultural productivity. Both John Deere and Case IH autonomous systems contribute to environmental sustainability through multiple mechanisms that address key environmental challenges facing modern agriculture.

Autonomous tractors enable precision application of agricultural inputs, reducing overall chemical usage while maintaining effective pest control and crop nutrition through targeted application strategies. This precision approach minimizes environmental contamination from agricultural chemicals while reducing input costs and improving crop health through optimized application timing and placement.

The optimized travel patterns and operational efficiency of autonomous systems contribute to reduced fuel consumption and lower greenhouse gas emissions compared to traditional farming operations. These environmental benefits accumulate over time to create measurable improvements in the carbon footprint of agricultural operations while reducing operational costs through improved fuel efficiency.

Autonomous systems enable implementation of conservation agriculture practices such as controlled traffic farming, which minimizes soil compaction and erosion while improving soil health and water retention. These practices contribute to long-term environmental sustainability while improving agricultural productivity through enhanced soil quality and nutrient retention.

Technology Integration and Farm Management Systems

The successful implementation of autonomous tractor technology requires seamless integration with existing farm management systems and agricultural technologies to maximize operational efficiency and data utilization. Both John Deere and Case IH have developed comprehensive integration strategies that enable autonomous systems to work effectively within broader agricultural technology ecosystems while providing farmers with unified control and monitoring capabilities.

John Deere’s Operations Center platform provides centralized management of autonomous equipment along with comprehensive farm management tools that integrate data from multiple sources to provide holistic insights into farm operations. This integration enables farmers to coordinate autonomous operations with other farm activities while maintaining complete visibility into equipment performance, field conditions, and operational metrics.

Case IH’s approach to technology integration emphasizes compatibility with third-party agricultural technologies and open data standards that enable farmers to integrate autonomous systems with existing farm management software and equipment from multiple manufacturers. This flexibility allows farmers to maintain their preferred agricultural technology ecosystems while adding autonomous capabilities to their operations.

Both manufacturers provide comprehensive training and support programs that help farmers effectively utilize autonomous technology and integrate these systems into their existing operational workflows. These support programs are essential for maximizing the benefits of autonomous technology while ensuring safe and efficient operation across diverse farming environments.

Future Developments and Market Trends

The autonomous agricultural equipment market continues to evolve rapidly, with both John Deere and Case IH investing heavily in next-generation technologies that promise to further revolutionize farming practices through enhanced artificial intelligence capabilities, improved sensor technologies, and expanded autonomous functionality. These future developments will likely focus on increased operational autonomy, improved decision-making capabilities, and enhanced integration with emerging agricultural technologies.

Artificial intelligence advancements will enable autonomous systems to make increasingly sophisticated farming decisions based on complex data analysis and predictive modeling capabilities. Future autonomous tractors may be capable of autonomous crop planning, pest management strategies, and yield optimization decisions that currently require human expertise and intervention.

The integration of 5G connectivity and edge computing technologies will enable real-time data sharing between autonomous equipment, farm management systems, and agricultural service providers, creating opportunities for collaborative farming strategies and shared resource optimization across multiple farms and agricultural operations.

Both manufacturers are exploring the development of specialized autonomous equipment for specific agricultural applications, including autonomous harvesting systems, precision spraying equipment, and livestock management robots that will expand the scope of autonomous technology in agriculture beyond traditional tractor operations.

The continued evolution of autonomous agricultural technology promises to democratize access to precision agriculture capabilities while enabling sustainable farming practices that address global food security challenges and environmental sustainability requirements. The competition between industry leaders like John Deere and Case IH drives continued innovation and improvement in autonomous technology, benefiting farmers worldwide through enhanced capabilities and competitive pricing.

Disclaimer

This article is for informational purposes only and does not constitute professional agricultural or investment advice. The views expressed are based on current understanding of autonomous agricultural technology and market conditions. Farmers should conduct thorough research, consult with agricultural experts, and consider their specific operational requirements when evaluating autonomous tractor technology. Equipment performance, costs, and benefits may vary based on specific applications, field conditions, and operational factors. Always follow manufacturer guidelines and safety protocols when operating autonomous agricultural equipment.