The convergence of artificial intelligence, Internet of Things sensors, and advanced simulation technologies has given birth to one of the most transformative innovations in modern industrial applications: AI-powered digital twins. These sophisticated virtual replicas of physical systems represent a paradigm shift in how organizations monitor, analyze, and optimize their operations, creating unprecedented opportunities for predictive maintenance, performance optimization, and strategic decision-making across diverse industries ranging from manufacturing and healthcare to smart cities and aerospace engineering.

Discover the latest AI trends and innovations that are shaping the future of digital twin technology and its applications across various sectors. The integration of artificial intelligence into digital twin frameworks has elevated these virtual models from static representations to dynamic, learning systems capable of real-time analysis, predictive insights, and autonomous optimization that continuously evolve alongside their physical counterparts.

Understanding AI Digital Twins Technology

AI digital twins represent the sophisticated evolution of traditional digital modeling, incorporating machine learning algorithms, real-time data processing capabilities, and predictive analytics to create intelligent virtual representations that mirror the behavior, performance, and characteristics of physical assets, processes, or systems. Unlike conventional digital models that provide static snapshots of physical entities, AI-enhanced digital twins continuously learn from incoming data streams, adapt to changing conditions, and provide actionable insights that enable proactive decision-making and optimization strategies.

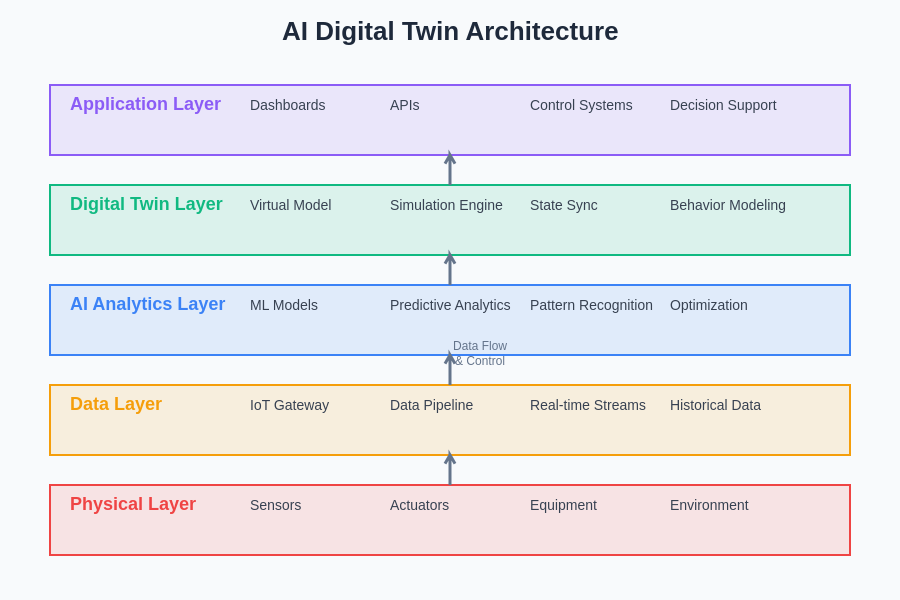

The fundamental architecture of AI digital twins encompasses multiple interconnected layers, including data acquisition systems that collect real-time information from IoT sensors and monitoring devices, advanced analytics engines that process and interpret this data using machine learning algorithms, simulation environments that model complex system behaviors and interactions, and intelligent interfaces that present insights and recommendations to human operators. This comprehensive approach enables organizations to gain unprecedented visibility into their operations while developing predictive capabilities that can anticipate potential issues, optimize performance parameters, and identify opportunities for improvement before they manifest in the physical world.

The transformative power of AI digital twins lies in their ability to bridge the gap between physical reality and digital intelligence, creating a continuous feedback loop that enhances both virtual understanding and physical performance. Through sophisticated algorithms that can detect patterns, anomalies, and trends in vast datasets, these systems provide organizations with the tools necessary to move from reactive maintenance strategies to proactive optimization approaches that maximize efficiency, minimize downtime, and reduce operational costs across diverse applications and industries.

The comprehensive architecture of AI digital twins encompasses multiple interconnected layers that work together to create intelligent virtual representations. From the physical sensor layer collecting real-time data to the application layer providing actionable insights, each component plays a crucial role in delivering the sophisticated capabilities that make digital twins such powerful tools for modern organizations.

Industrial Manufacturing Applications

The manufacturing sector has emerged as one of the primary beneficiaries of AI digital twin technology, with applications spanning from individual machine monitoring to comprehensive factory-wide optimization systems. Smart factories utilize digital twins to create virtual replicas of production lines, enabling manufacturers to simulate different operational scenarios, optimize resource allocation, and predict maintenance requirements before equipment failures occur. These systems continuously monitor key performance indicators such as production throughput, energy consumption, quality metrics, and equipment health, providing real-time insights that enable immediate adjustments to maintain optimal performance levels.

Predictive maintenance applications represent one of the most impactful implementations of AI digital twins in manufacturing environments. By analyzing historical performance data, current operational parameters, and environmental conditions, these systems can accurately predict when machinery components are likely to fail, enabling maintenance teams to schedule interventions during planned downtime periods rather than responding to unexpected breakdowns. This proactive approach significantly reduces maintenance costs, minimizes production disruptions, and extends equipment lifespan while maintaining consistent product quality and safety standards.

Enhance your AI capabilities with Claude’s advanced reasoning to develop sophisticated digital twin solutions that can handle complex manufacturing scenarios and provide actionable insights for operational optimization. The integration of AI-powered digital twins in manufacturing has also enabled advanced quality control systems that can detect defects, variations, and anomalies in real-time, automatically adjusting production parameters to maintain consistent product standards and reduce waste throughout the manufacturing process.

Healthcare and Medical Device Monitoring

The healthcare industry has embraced AI digital twins as powerful tools for patient care optimization, medical device monitoring, and treatment planning, creating virtual representations of patients, organs, and medical equipment that enable personalized healthcare delivery and improved patient outcomes. Digital twins of medical devices such as pacemakers, insulin pumps, and ventilators provide continuous monitoring capabilities that can detect anomalies, predict potential failures, and optimize device performance based on individual patient needs and responses.

Personalized medicine applications utilize digital twins to create virtual patient models that incorporate genetic information, medical history, lifestyle factors, and real-time physiological data to simulate treatment responses and optimize therapeutic interventions. These sophisticated models enable healthcare providers to test different treatment scenarios in virtual environments before implementing them in real-world clinical settings, reducing risks, improving treatment efficacy, and minimizing adverse reactions through data-driven decision-making processes.

Hospital operations have been significantly enhanced through digital twin implementations that monitor and optimize facility performance, including patient flow management, resource allocation, equipment utilization, and environmental controls. These systems provide hospital administrators with comprehensive visibility into operational efficiency while enabling predictive analytics that can anticipate capacity constraints, optimize staffing levels, and improve patient satisfaction through more efficient service delivery and resource management strategies.

Smart City Infrastructure Management

Urban planning and infrastructure management have been revolutionized through the implementation of AI digital twins that create comprehensive virtual representations of entire cities, enabling municipal authorities to optimize traffic flow, manage energy consumption, improve public safety, and enhance citizen services through data-driven decision-making processes. Smart city digital twins integrate data from thousands of sensors, cameras, and monitoring devices to provide real-time insights into urban systems performance while predicting future infrastructure needs and potential challenges.

Traffic management systems utilizing AI digital twins can simulate different traffic scenarios, optimize signal timing, and predict congestion patterns to improve urban mobility and reduce environmental impact through more efficient transportation networks. These systems analyze historical traffic data, real-time vehicle movements, weather conditions, and special events to provide dynamic routing recommendations and optimize public transportation schedules that minimize travel times and improve citizen satisfaction with urban mobility services.

Environmental monitoring applications leverage digital twin technology to track air quality, noise levels, water quality, and energy consumption patterns across urban areas, providing city officials with the information necessary to implement targeted interventions that improve public health and environmental sustainability. These systems can predict the impact of policy changes, infrastructure modifications, and development projects on urban environmental conditions, enabling more informed decision-making that balances economic development with environmental protection and citizen welfare.

Explore comprehensive AI research capabilities with Perplexity to stay informed about the latest developments in smart city technologies and digital twin implementations that are transforming urban management and citizen services worldwide. The integration of AI into urban digital twins has enabled predictive capabilities that can anticipate infrastructure maintenance needs, optimize resource allocation, and improve emergency response coordination through real-time situational awareness and intelligent decision support systems.

Aerospace and Automotive Engineering

The aerospace industry has pioneered the use of AI digital twins for aircraft design, manufacturing, and maintenance applications, creating virtual replicas of aircraft systems that enable predictive maintenance, performance optimization, and safety enhancement throughout the entire aircraft lifecycle. These sophisticated digital models incorporate real-time flight data, weather conditions, maintenance history, and operational parameters to provide comprehensive insights into aircraft performance while predicting potential issues before they impact flight safety or operational efficiency.

Aircraft engine monitoring represents one of the most critical applications of digital twin technology, where virtual replicas continuously analyze engine performance data, predict component wear patterns, and optimize maintenance schedules to ensure maximum reliability and efficiency. These systems can detect subtle changes in engine behavior that may indicate developing problems, enabling maintenance teams to address issues during scheduled maintenance periods rather than experiencing unexpected failures that could result in flight delays, cancellations, or safety concerns.

Automotive manufacturers utilize AI digital twins throughout the vehicle development and production process, from initial design optimization to manufacturing quality control and post-sale performance monitoring. Connected vehicles equipped with numerous sensors provide continuous data streams that feed into digital twin models, enabling manufacturers to monitor vehicle performance, predict maintenance needs, and identify potential safety issues across entire vehicle fleets while providing valuable insights for future product development and improvement initiatives.

Energy Sector Optimization

The energy industry has leveraged AI digital twins to optimize power generation, distribution, and consumption across renewable and traditional energy sources, creating intelligent grid management systems that can balance supply and demand while minimizing environmental impact and operational costs. Wind farms utilize digital twins to optimize turbine placement, predict maintenance requirements, and maximize energy generation efficiency based on weather patterns, equipment performance, and grid demand fluctuations.

Smart grid implementations incorporate digital twin technology to create comprehensive virtual representations of electrical distribution networks, enabling utility companies to predict equipment failures, optimize energy flow, and integrate renewable energy sources more effectively into existing grid infrastructure. These systems provide real-time monitoring of grid performance while predicting future energy demand patterns and identifying opportunities for efficiency improvements that reduce costs and environmental impact.

Oil and gas operations utilize digital twins to monitor pipeline integrity, optimize drilling operations, and predict equipment maintenance needs across complex industrial facilities and remote operational sites. These systems can detect potential leaks, corrosion, and equipment failures before they result in environmental damage or operational disruptions, enabling proactive maintenance strategies that improve safety, reduce costs, and minimize environmental impact throughout the energy production and distribution process.

Agricultural and Environmental Applications

Modern agriculture has embraced AI digital twins to optimize crop production, monitor soil conditions, and predict harvest yields through comprehensive farm management systems that integrate weather data, soil sensors, satellite imagery, and historical agricultural data. These digital farming solutions enable precision agriculture approaches that optimize resource utilization, minimize environmental impact, and maximize crop yields through data-driven decision-making processes that consider multiple variables affecting agricultural productivity.

Livestock monitoring applications utilize digital twins to track animal health, optimize feeding schedules, and predict breeding outcomes through comprehensive animal welfare management systems that incorporate behavioral data, health metrics, and environmental conditions. These systems provide farmers with early warning capabilities for disease detection, optimize resource allocation for animal care, and improve overall livestock productivity while maintaining high standards of animal welfare and sustainable farming practices.

Environmental conservation efforts have been enhanced through digital twin implementations that monitor ecosystem health, predict environmental changes, and optimize conservation strategies across diverse natural habitats and protected areas. These systems integrate data from multiple sources including satellite imagery, sensor networks, and field observations to provide comprehensive insights into ecosystem dynamics while predicting the impact of climate change, human activities, and conservation interventions on biodiversity and environmental sustainability.

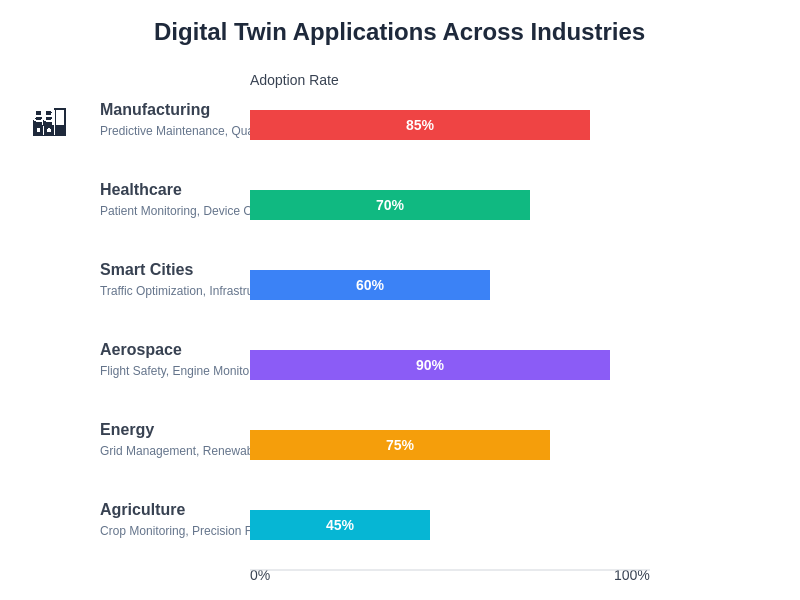

The adoption of digital twin technology varies significantly across different industries, with manufacturing and aerospace leading the way due to their complex operational requirements and high-value assets. Each sector leverages digital twins differently, from predictive maintenance in manufacturing to patient monitoring in healthcare, demonstrating the versatile nature of this transformative technology.

Implementation Challenges and Considerations

The successful implementation of AI digital twins requires careful consideration of multiple technical, organizational, and economic factors that can significantly impact project outcomes and return on investment. Data quality and integration challenges represent one of the primary obstacles, as digital twins require access to high-quality, real-time data from multiple sources that may utilize different formats, protocols, and quality standards. Organizations must invest in robust data infrastructure, standardization processes, and quality assurance systems to ensure that digital twin models receive accurate and consistent input data.

Cybersecurity considerations become increasingly critical as digital twins create new attack surfaces and potential vulnerabilities that malicious actors could exploit to gain access to sensitive operational data or disrupt physical systems. Organizations must implement comprehensive security frameworks that protect data transmission, storage, and processing systems while ensuring that digital twin implementations do not compromise the security of physical assets or operational systems.

The complexity of AI digital twin systems requires specialized expertise in multiple domains including data science, system integration, domain-specific knowledge, and cybersecurity, creating significant skill gaps that organizations must address through training programs, strategic hiring, or partnerships with specialized technology providers. The interdisciplinary nature of digital twin projects demands collaboration between IT professionals, operational experts, and business stakeholders to ensure successful implementation and adoption.

Economic Impact and Return on Investment

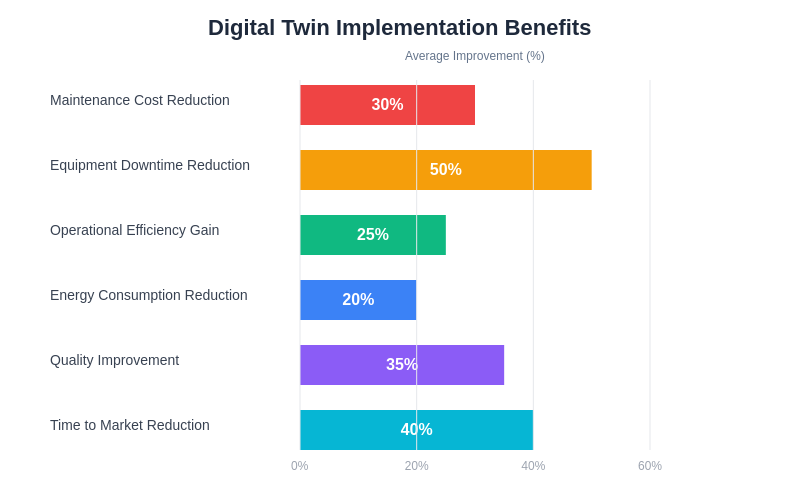

Organizations implementing AI digital twins typically experience significant economic benefits through reduced operational costs, improved efficiency, and enhanced decision-making capabilities that translate into measurable improvements in productivity, quality, and profitability. Predictive maintenance applications alone can reduce maintenance costs by twenty to thirty percent while decreasing equipment downtime by up to fifty percent, resulting in substantial improvements in operational efficiency and customer satisfaction.

The ability to simulate different operational scenarios and optimize system performance through digital twin models enables organizations to identify cost reduction opportunities, improve resource utilization, and enhance productivity without the risks and expenses associated with physical experimentation. These optimization capabilities can result in energy savings, waste reduction, and improved asset utilization that generate ongoing operational benefits and competitive advantages.

Investment in digital twin technology typically requires substantial upfront costs for infrastructure development, system integration, and staff training, but organizations that successfully implement these systems often achieve positive return on investment within eighteen to twenty-four months through operational improvements, cost reductions, and enhanced decision-making capabilities that justify the initial investment and ongoing operational expenses.

The measurable benefits of digital twin implementation span multiple operational areas, with particularly significant improvements in maintenance cost reduction, equipment downtime minimization, and overall operational efficiency. These quantifiable improvements demonstrate the substantial value proposition that well-executed digital twin projects can deliver to organizations across various industries and applications.

Future Developments and Emerging Trends

The future evolution of AI digital twins will be driven by advances in artificial intelligence, edge computing, quantum computing, and immersive technologies that will enable more sophisticated modeling capabilities, faster processing speeds, and enhanced user interfaces that make digital twin insights more accessible and actionable for diverse user communities. Machine learning algorithms will become more sophisticated in their ability to detect patterns, predict outcomes, and recommend optimization strategies that adapt to changing conditions and evolving operational requirements.

Integration with emerging technologies such as augmented reality, virtual reality, and mixed reality will create new possibilities for visualizing and interacting with digital twin data, enabling more intuitive and immersive experiences that enhance human understanding and decision-making capabilities. These immersive interfaces will make digital twin insights more accessible to non-technical users while providing new ways to explore complex system relationships and optimization opportunities.

The democratization of digital twin technology through cloud-based platforms, standardized development frameworks, and industry-specific solutions will make these powerful tools accessible to smaller organizations and specialized applications that were previously unable to justify the investment in custom digital twin development. This broader adoption will accelerate innovation and create new opportunities for collaboration and knowledge sharing across industries and applications.

Disclaimer

This article is for informational purposes only and does not constitute professional advice regarding digital twin implementation or investment decisions. The technologies and applications described are based on current industry developments and may vary significantly depending on specific use cases, organizational requirements, and technical constraints. Organizations considering digital twin implementations should conduct thorough evaluations of their specific needs, capabilities, and constraints while consulting with qualified technology professionals and industry experts to ensure successful project outcomes.