The intersection of artificial intelligence and materials science represents one of the most promising frontiers in scientific discovery, fundamentally transforming how researchers identify, design, and synthesize new compounds with unprecedented properties. This revolutionary approach leverages the computational power of machine learning algorithms to accelerate materials discovery processes that traditionally required decades of experimental trial and error, opening new pathways to breakthrough materials that could solve some of humanity’s most pressing technological challenges.

Stay updated with the latest AI scientific breakthroughs as researchers continue to push the boundaries of what’s possible in computational materials science. The convergence of advanced AI algorithms with sophisticated materials characterization techniques has created a paradigm shift that is reshaping our understanding of structure-property relationships and enabling the rational design of materials with tailored functionalities.

The Revolutionary Impact of AI on Materials Discovery

Traditional materials discovery has long been characterized by serendipitous findings, extensive experimental screening, and iterative optimization processes that could span multiple decades before yielding commercially viable results. The integration of artificial intelligence into materials science has fundamentally altered this landscape by introducing predictive capabilities that can rapidly evaluate millions of potential material combinations, identify promising candidates, and guide experimental efforts toward the most likely successful outcomes.

Machine learning algorithms excel at recognizing complex patterns within vast datasets of materials properties, enabling researchers to establish previously unknown correlations between atomic structure, chemical composition, and macroscopic material behavior. This computational approach has proven particularly valuable in predicting material properties such as bandgap energies, mechanical strength, thermal conductivity, and catalytic activity without requiring extensive experimental validation for each candidate compound.

The acceleration of discovery timelines represents perhaps the most significant advantage of AI-driven materials research. Where traditional approaches might require years to identify and optimize a single promising compound, machine learning models can screen thousands of potential materials in a matter of hours or days, dramatically compressing the timeline from initial concept to practical application and enabling rapid response to emerging technological demands.

Computational Frameworks Driving Materials Innovation

The foundation of AI-powered materials discovery rests upon sophisticated computational frameworks that integrate quantum mechanical calculations, thermodynamic modeling, and machine learning algorithms to predict material properties with remarkable accuracy. These frameworks leverage density functional theory calculations to generate training datasets containing detailed information about atomic structures, electronic properties, and formation energies for thousands of known compounds.

Experience advanced AI reasoning capabilities with Claude to understand complex materials science relationships and accelerate your research workflow with intelligent analysis and insight generation. Modern computational approaches combine first-principles calculations with data-driven machine learning models to create hybrid systems that capture both the fundamental physics governing material behavior and the empirical relationships discovered through large-scale data analysis.

The development of materials informatics databases has been crucial in enabling these AI-driven approaches. Comprehensive repositories such as the Materials Project, NOMAD, and AFLOWLIB contain millions of calculated and experimental material properties, providing the extensive training datasets necessary for developing robust machine learning models. These databases continue to grow through automated high-throughput calculations and experimental data integration, creating increasingly comprehensive knowledge bases for AI-driven discovery efforts.

Machine Learning Algorithms Transforming Materials Research

The application of various machine learning algorithms to materials science has revealed unique strengths and capabilities for different aspects of the discovery process. Neural networks have demonstrated exceptional performance in predicting complex materials properties by learning intricate relationships between atomic structure and macroscopic behavior, particularly excelling in scenarios where traditional analytical approaches prove insufficient.

Graph neural networks have emerged as particularly powerful tools for materials science applications due to their ability to naturally represent the complex three-dimensional structures of crystalline materials. These algorithms can capture the connectivity patterns between atoms and the influence of local chemical environments on material properties, making them ideally suited for predicting properties that depend on both local and global structural features.

Reinforcement learning algorithms have shown promise in optimizing materials synthesis conditions and exploring chemical space more efficiently than traditional optimization approaches. These methods can learn from experimental feedback to identify optimal processing parameters, reaction conditions, and composition ranges that maximize desired material properties while minimizing unwanted characteristics.

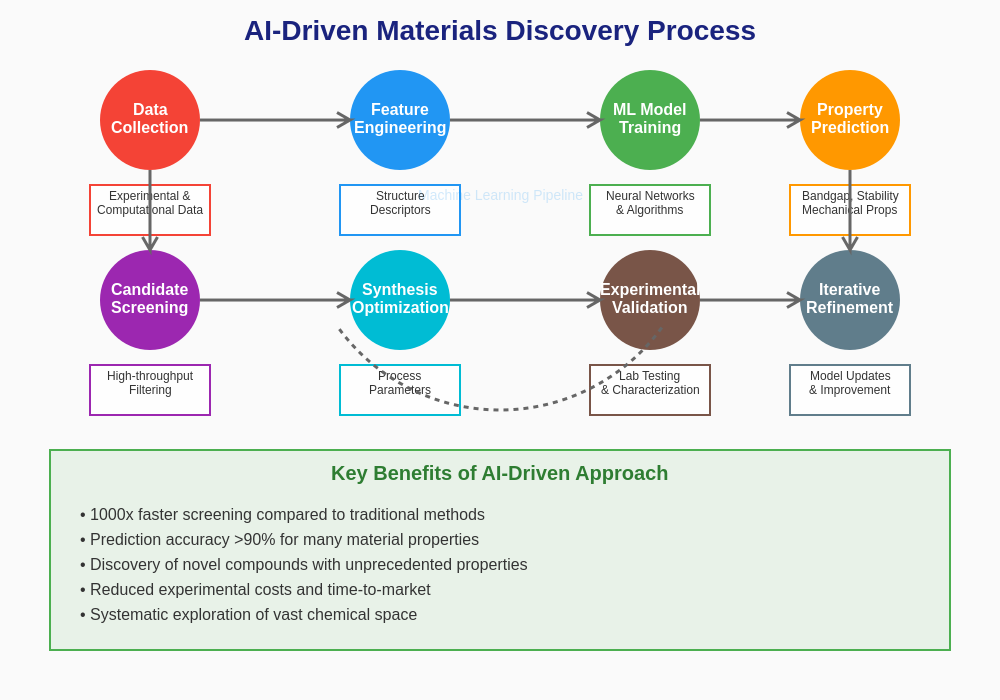

The integration of multiple machine learning approaches into comprehensive materials discovery pipelines has enabled researchers to tackle increasingly complex challenges in materials design. These multi-modal systems combine the strengths of different algorithms to address various aspects of the discovery process, from initial screening and property prediction to synthesis optimization and experimental validation. The systematic approach to AI-driven materials discovery encompasses the entire research pipeline from data collection through experimental validation, demonstrating how machine learning algorithms can be integrated at every stage to accelerate the identification and development of novel materials with targeted properties.

Breakthrough Applications in Compound Discovery

The practical impact of AI-driven materials discovery has become evident through numerous breakthrough applications across diverse technological domains. In the field of energy storage, machine learning algorithms have identified novel battery electrode materials with superior capacity, stability, and charging rates compared to conventional materials. These discoveries have accelerated the development of next-generation batteries for electric vehicles and grid-scale energy storage applications.

Catalysis research has been particularly transformed by AI approaches, with machine learning models successfully predicting catalytic activity and selectivity for various chemical reactions. These predictions have guided the development of more efficient catalysts for industrial processes, environmental remediation applications, and sustainable chemical synthesis pathways, resulting in significant improvements in process efficiency and environmental impact.

The discovery of new superconducting materials represents another area where AI has made substantial contributions. Machine learning models have identified previously unknown superconducting compounds and predicted their critical temperatures, guiding experimental efforts toward materials with enhanced superconducting properties that could enable revolutionary advances in power transmission, magnetic levitation, and quantum computing technologies.

Advanced Characterization Through AI Integration

Modern materials characterization increasingly relies on AI-enhanced analytical techniques that can extract meaningful information from complex experimental data with unprecedented speed and accuracy. Machine learning algorithms have been successfully applied to interpret X-ray diffraction patterns, electron microscopy images, and spectroscopic measurements, enabling automated identification of crystal structures, defects, and phase compositions.

Leverage Perplexity’s research capabilities to stay current with the latest developments in AI-powered materials characterization techniques and experimental methodologies. The integration of AI into experimental workflows has enabled real-time analysis and optimization of synthesis conditions, allowing researchers to make immediate adjustments based on preliminary characterization results.

Automated scanning probe microscopy systems enhanced with machine learning algorithms can now autonomously identify interesting features, optimize imaging conditions, and perform targeted measurements without human intervention. This automation has dramatically increased the throughput of detailed materials characterization while ensuring consistent quality and reducing operator bias in data collection and analysis.

Predictive Modeling for Materials Properties

The development of accurate predictive models for materials properties represents a cornerstone achievement in AI-driven materials science. These models can predict a wide range of properties including mechanical strength, thermal stability, electrical conductivity, optical properties, and chemical reactivity based solely on structural and compositional information, eliminating the need for time-consuming experimental measurements during initial screening phases.

Advanced machine learning models have achieved remarkable accuracy in predicting formation energies, enabling researchers to assess the thermodynamic stability of hypothetical compounds before attempting synthesis. This capability is particularly valuable for identifying metastable phases and understanding the conditions necessary for successful synthesis of novel materials with desired properties.

The prediction of transport properties such as ionic conductivity and thermal conductivity has proven challenging for traditional computational methods but has been successfully addressed through machine learning approaches. These predictive capabilities have accelerated the development of solid-state electrolytes for batteries, thermoelectric materials for energy harvesting, and thermal management materials for electronic applications.

Accelerating Synthesis and Processing Optimization

Machine learning algorithms have revolutionized the optimization of materials synthesis and processing conditions by identifying optimal parameter combinations from high-dimensional parameter spaces more efficiently than traditional experimental design approaches. These algorithms can learn from limited experimental data to predict the outcomes of untested synthesis conditions, guiding researchers toward successful synthesis routes while minimizing resource consumption and experimental time.

The integration of AI with automated synthesis equipment has enabled the development of autonomous materials discovery systems that can design experiments, execute synthesis procedures, characterize resulting materials, and iterate on synthesis conditions without human intervention. These systems represent a significant step toward fully automated materials discovery laboratories that can operate continuously to explore chemical space systematically.

Process optimization through machine learning has proven particularly valuable for complex synthesis routes involving multiple reaction steps, temperature profiles, and atmospheric conditions. AI algorithms can identify subtle relationships between processing parameters and final material properties that might be missed through traditional experimental design approaches, leading to improved synthesis yields and enhanced material quality.

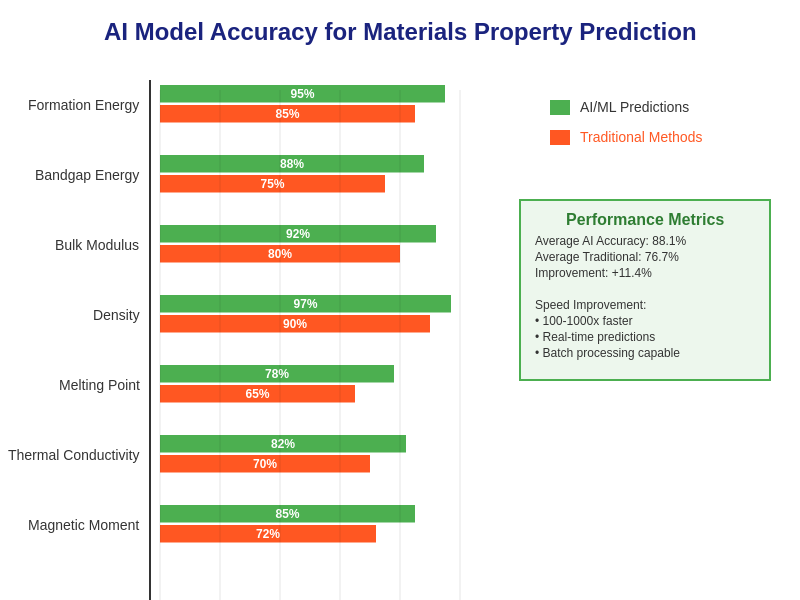

The validation of machine learning predictions through targeted experimental verification has become an essential component of AI-driven materials discovery workflows. This feedback loop enables continuous improvement of predictive models while building confidence in their reliability for guiding experimental efforts and reducing the risk of unsuccessful synthesis attempts. The remarkable accuracy achieved by modern AI models in predicting materials properties demonstrates the maturity of machine learning approaches in materials science, with performance metrics showcasing significant improvements over traditional computational methods across a wide range of fundamental materials properties.

Challenges and Limitations in AI Materials Science

Despite the remarkable successes of AI in materials discovery, several significant challenges continue to limit the full potential of these approaches. The quality and completeness of training datasets represent perhaps the most critical limitation, as machine learning models can only be as reliable as the data upon which they are trained. Gaps in experimental data, measurement uncertainties, and systematic errors in computational calculations can all propagate through to affect model predictions.

The interpretability of complex machine learning models poses another significant challenge for materials scientists who need to understand the physical principles underlying predicted relationships. While deep learning models may achieve high predictive accuracy, their black-box nature makes it difficult to extract fundamental insights about structure-property relationships that could guide broader materials design principles.

Scaling challenges emerge when attempting to apply AI methods to increasingly complex materials systems involving multiple phases, interfaces, and hierarchical structures. The computational cost of generating training data for complex systems can become prohibitive, while the dimensionality of the design space may exceed the capacity of current machine learning approaches to provide meaningful guidance.

Emerging Frontiers in Computational Materials Design

The future of AI-driven materials discovery promises even more sophisticated approaches that integrate multiple scales of modeling, from quantum mechanical calculations to continuum-level simulations, within unified machine learning frameworks. These multi-scale approaches will enable the design of materials with hierarchical structures and complex functionalities that emerge from interactions across multiple length and time scales.

The development of foundation models specifically designed for materials science represents an exciting frontier that could dramatically expand the capabilities of AI-driven discovery. These large-scale models, trained on comprehensive materials databases, could provide general-purpose capabilities for property prediction, synthesis optimization, and materials design across diverse application domains.

Active learning approaches that intelligently select the most informative experiments for model improvement are becoming increasingly sophisticated, enabling more efficient exploration of chemical space and faster convergence toward optimal materials. These methods promise to minimize the experimental effort required for discovering new materials while maximizing the information gained from each synthesis attempt.

Impact on Industrial Applications and Manufacturing

The translation of AI-discovered materials from laboratory concepts to industrial applications represents a critical next step that requires integration of predictive models with manufacturing process optimization and quality control systems. Machine learning approaches are increasingly being applied to predict manufacturability, scalability, and cost-effectiveness of novel materials, ensuring that discovered compounds can be successfully commercialized.

Quality control and process monitoring in materials manufacturing have been enhanced through AI systems that can detect deviations from optimal processing conditions, predict equipment failures, and optimize production parameters in real-time. These capabilities are essential for maintaining consistent quality when scaling up production of AI-discovered materials from laboratory quantities to industrial volumes.

The integration of AI throughout the entire materials value chain, from discovery through manufacturing to end-of-life recycling, promises to create more sustainable and efficient materials ecosystems. Machine learning models can optimize resource utilization, minimize waste generation, and identify opportunities for materials reuse and recycling, contributing to circular economy principles in materials development.

Collaborative Research Networks and Data Sharing

The success of AI-driven materials discovery increasingly depends on collaborative research networks that facilitate data sharing, model development, and experimental validation across institutions and disciplines. International initiatives such as the Materials Genome Initiative and European Materials Modelling Council are fostering collaboration and standardization of data formats, computational methods, and experimental protocols.

Open-source software platforms and computational tools have democratized access to AI-powered materials discovery capabilities, enabling researchers worldwide to contribute to and benefit from advances in computational materials science. These platforms facilitate reproducibility, enable collaborative model development, and accelerate the adoption of AI methods across the materials research community.

The establishment of standardized benchmarks and validation datasets has become crucial for comparing the performance of different machine learning approaches and ensuring the reliability of predictive models. These standards help establish trust in AI-driven predictions and facilitate the adoption of these methods in industrial research and development environments.

Future Prospects and Technological Implications

The continued advancement of AI in materials science promises to unlock unprecedented capabilities for designing materials with precisely tailored properties for specific applications. Future developments may include the ability to design materials with multiple conflicting property requirements, such as materials that are simultaneously strong and lightweight, conductive and transparent, or stable and reactive under different conditions.

The integration of AI with emerging experimental techniques such as in-situ characterization, automated synthesis, and high-throughput screening will create increasingly powerful materials discovery ecosystems. These integrated systems will enable real-time optimization of materials properties during synthesis and processing, leading to more efficient development of novel materials with enhanced performance characteristics.

As AI methods become more sophisticated and data resources continue to expand, the scope of materials discovery will extend to increasingly complex systems including multi-component alloys, composite materials, and biomaterials with intricate structures and functionalities. The ability to design materials at the intersection of different disciplines, such as bio-inspired materials and quantum materials, will open new frontiers for technological innovation and scientific discovery.

The democratization of materials discovery through AI tools will enable smaller research groups and developing countries to participate more effectively in cutting-edge materials research, potentially accelerating global innovation and addressing region-specific technological challenges through locally relevant materials solutions.

Disclaimer

This article is for informational purposes only and does not constitute professional scientific or technical advice. The views expressed are based on current understanding of AI applications in materials science and their potential impact on research and development. Readers should conduct their own research and consult with qualified experts when implementing AI-driven approaches in materials discovery. The effectiveness and accuracy of AI predictions may vary depending on specific applications, data quality, and model limitations. Results from AI-guided materials discovery should always be validated through appropriate experimental verification before practical implementation.