The construction industry stands at the precipice of a technological revolution, where artificial intelligence is fundamentally transforming how projects are conceived, managed, and executed. This transformation extends far beyond simple automation, encompassing sophisticated project management systems that can predict delays before they occur, safety monitoring solutions that prevent accidents through real-time analysis, and intelligent resource allocation that maximizes efficiency while minimizing waste. The integration of AI into construction workflows represents a paradigm shift that addresses longstanding challenges while unlocking unprecedented opportunities for innovation and growth.

Explore the latest AI trends shaping construction as the industry embraces digital transformation through machine learning, computer vision, and predictive analytics. The convergence of these technologies with traditional construction practices is creating a new era of smart construction that prioritizes safety, efficiency, and sustainability while maintaining the human expertise that remains essential for successful project delivery.

The Evolution of Smart Construction Management

Traditional construction project management has long relied on experience-based decision making, manual scheduling processes, and reactive problem-solving approaches that often result in cost overruns, schedule delays, and safety incidents. The introduction of AI-powered systems has fundamentally altered this landscape by providing construction managers with intelligent tools that can process vast amounts of data from multiple sources, identify patterns that human analysis might miss, and generate actionable insights that inform critical decision-making processes throughout the project lifecycle.

Modern AI systems in construction leverage machine learning algorithms trained on historical project data to predict potential issues, optimize resource allocation, and suggest proactive interventions that prevent problems before they materialize. These systems can analyze everything from weather patterns and material delivery schedules to worker productivity metrics and equipment utilization rates, creating comprehensive predictive models that enable more informed decision-making and improved project outcomes.

The transformation extends to real-time project monitoring, where AI systems continuously analyze data streams from various sources including IoT sensors, drones, cameras, and mobile devices to provide construction managers with unprecedented visibility into project progress, potential bottlenecks, and emerging risks. This comprehensive monitoring capability enables rapid response to changing conditions and helps maintain project momentum even in the face of unexpected challenges.

Revolutionary Safety Monitoring Systems

Construction sites have historically been among the most dangerous work environments, with injury rates significantly higher than most other industries. AI-powered safety monitoring systems are revolutionizing this aspect of construction by providing continuous, intelligent surveillance that can identify potential hazards, monitor compliance with safety protocols, and alert supervisors to dangerous situations before accidents occur.

Computer vision systems equipped with advanced machine learning algorithms can now monitor construction sites in real-time, identifying workers who are not wearing proper personal protective equipment, detecting unsafe behaviors such as working at dangerous heights without proper fall protection, and recognizing hazardous conditions such as unstable scaffolding or improperly stored materials. These systems can process video feeds from multiple cameras simultaneously, providing comprehensive coverage that would be impossible to achieve through human supervision alone.

Discover advanced AI capabilities with Claude for comprehensive analysis and decision-making support that can be applied to construction safety protocols and risk management strategies. The integration of sophisticated AI analysis with construction safety management creates powerful systems that can learn from past incidents, predict potential risks, and recommend preventive measures tailored to specific project conditions and requirements.

The predictive capabilities of AI safety systems extend beyond immediate hazard detection to include analysis of environmental conditions, worker fatigue patterns, and equipment maintenance schedules that could contribute to safety risks. By analyzing historical accident data alongside current project conditions, these systems can identify high-risk scenarios and recommend specific interventions to prevent incidents before they occur.

Intelligent Resource Optimization

Resource management in construction projects involves complex coordination of materials, equipment, and personnel across multiple phases of development. AI systems excel at this type of multi-variable optimization, using sophisticated algorithms to balance competing demands and constraints while maximizing overall project efficiency. These systems can analyze supply chain data, weather forecasts, labor availability, and project schedules to optimize resource allocation and minimize waste.

Machine learning algorithms can predict material requirements with remarkable accuracy by analyzing project specifications, historical consumption data, and progress patterns. This predictive capability enables more efficient procurement processes, reduces material waste, and minimizes storage requirements on construction sites. Similarly, AI systems can optimize equipment utilization by analyzing usage patterns, maintenance requirements, and project schedules to ensure that machinery is available when needed while minimizing idle time and unnecessary rental costs.

The optimization extends to workforce management, where AI systems can analyze productivity data, skill requirements, and project schedules to optimize crew assignments and work sequences. These systems can identify the most efficient combinations of workers for specific tasks, predict potential labor shortages, and suggest strategies for maintaining productivity even when faced with scheduling conflicts or resource constraints.

Predictive Analytics for Project Success

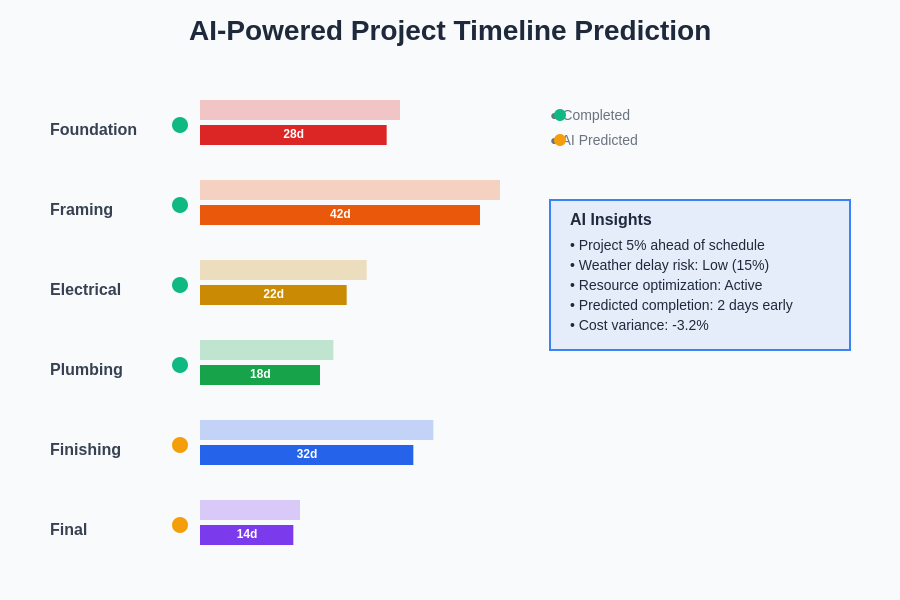

The power of AI in construction project management lies largely in its ability to analyze vast amounts of historical and real-time data to generate accurate predictions about project outcomes, potential risks, and optimal strategies for achieving success. Predictive analytics systems can process information from thousands of completed projects to identify patterns and factors that contribute to successful project delivery, enabling construction managers to make more informed decisions and proactively address potential challenges.

These systems can predict project completion dates with remarkable accuracy by analyzing current progress, remaining work scope, resource availability, and historical performance data. This predictive capability enables more reliable scheduling, better client communication, and more effective resource planning. Similarly, AI systems can predict cost overruns by analyzing spending patterns, change order frequency, and project complexity factors, enabling proactive budget management and cost control measures.

The integration of predictive analytics with project management workflows creates powerful systems that can continuously update predictions as new information becomes available, enabling construction managers to adapt their strategies in response to changing conditions while maintaining focus on project objectives and deliverables.

Advanced Quality Control and Inspection

Quality control in construction has traditionally relied on manual inspection processes that are time-consuming, subjective, and prone to human error. AI-powered quality control systems are transforming this aspect of construction by providing objective, comprehensive inspection capabilities that can identify defects, measure compliance with specifications, and document quality metrics throughout the construction process.

Computer vision systems can analyze photographs and video footage from construction sites to identify potential quality issues such as improper concrete pours, misaligned structural elements, or inadequate finishing work. These systems can compare actual construction against design specifications with precision that exceeds human capability, identifying deviations that might otherwise go unnoticed until later phases of construction when correction becomes more expensive and disruptive.

The documentation capabilities of AI quality control systems provide comprehensive records of construction quality that can be used for warranty purposes, regulatory compliance, and continuous improvement initiatives. These systems can generate detailed reports that include photographic evidence, measurement data, and compliance assessments that support both current project management and future project planning efforts.

Real-Time Progress Monitoring and Reporting

Traditional progress monitoring in construction relies on periodic inspections and manual reporting processes that provide limited visibility into day-to-day project activities and can result in delayed identification of problems or delays. AI-powered progress monitoring systems provide continuous, objective assessment of construction progress through automated analysis of site imagery, sensor data, and project documentation.

These systems can compare actual construction progress against planned schedules with remarkable accuracy, identifying areas where work is ahead of or behind schedule and providing early warning of potential delays. The automated nature of these systems ensures that progress assessments are conducted consistently and objectively, eliminating the subjectivity and potential biases that can affect manual progress reporting.

Enhance your analysis capabilities with Perplexity for comprehensive research and data gathering that supports construction project decision-making and strategic planning initiatives. The combination of multiple AI tools creates powerful analytical capabilities that can support complex construction management challenges and optimize project outcomes.

The integration of progress monitoring with project management systems enables automatic updating of schedules, budgets, and resource plans based on actual construction progress. This integration ensures that project information remains current and accurate, enabling more effective decision-making and communication with stakeholders throughout the project lifecycle.

Environmental and Sustainability Optimization

Construction projects have significant environmental impacts that extend beyond the immediate construction site to include material extraction, transportation, energy consumption, and waste generation. AI systems are increasingly being used to optimize these environmental factors while maintaining project efficiency and cost-effectiveness. These systems can analyze the environmental impact of different construction methods, materials, and schedules to identify opportunities for reducing the project’s overall carbon footprint.

Machine learning algorithms can optimize construction schedules to minimize energy consumption, reduce transportation requirements, and maximize the use of sustainable materials and methods. These systems can also monitor environmental conditions such as air quality, noise levels, and water usage to ensure compliance with environmental regulations while identifying opportunities for further improvement.

The long-term benefits of AI-driven environmental optimization extend beyond individual projects to support broader sustainability goals and regulatory compliance requirements. Construction companies that implement these systems can demonstrate their commitment to environmental stewardship while potentially reducing costs through more efficient resource utilization and waste reduction.

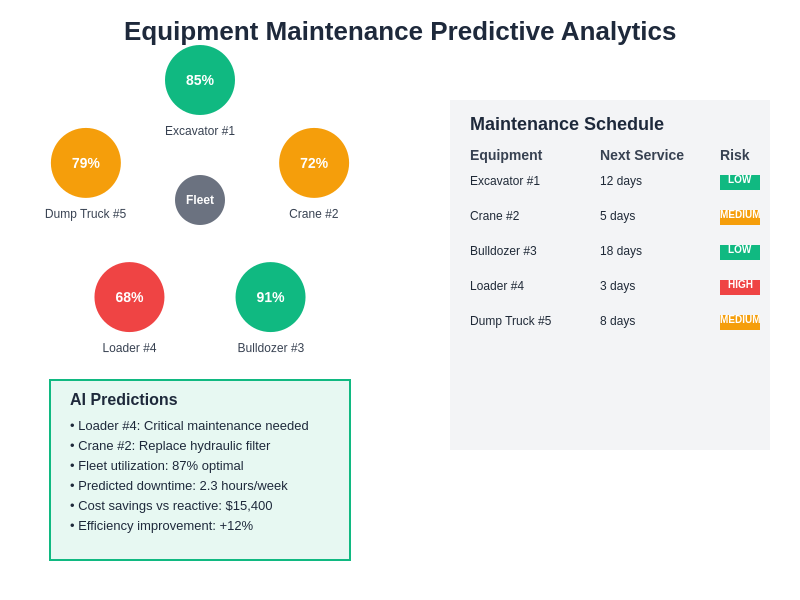

Equipment Management and Predictive Maintenance

Construction equipment represents a significant investment that requires careful management to maximize utilization while minimizing maintenance costs and downtime. AI systems excel at equipment management by analyzing usage patterns, maintenance history, and performance data to optimize equipment deployment and predict maintenance requirements before failures occur.

Predictive maintenance systems use machine learning algorithms to analyze sensor data from construction equipment to identify patterns that indicate potential failures or maintenance needs. These systems can predict when components are likely to fail, enabling proactive maintenance that prevents costly breakdowns and project delays. The predictive capabilities of these systems improve over time as they analyze more data and learn to recognize increasingly subtle indicators of potential problems.

The optimization of equipment utilization through AI analysis can significantly improve project efficiency and reduce costs by ensuring that equipment is deployed where it can provide the greatest value while minimizing idle time and unnecessary transportation between job sites.

Integration with Building Information Modeling

Building Information Modeling (BIM) has become an essential tool in modern construction, providing detailed digital representations of construction projects that facilitate planning, coordination, and communication. AI systems enhance BIM capabilities by adding intelligent analysis and automated updating capabilities that keep digital models synchronized with actual construction progress and conditions.

AI-powered BIM systems can automatically update models based on progress monitoring data, ensuring that digital representations remain accurate throughout the construction process. These systems can also analyze BIM data to identify potential conflicts, optimize construction sequences, and suggest improvements to design or construction methods that could improve project outcomes.

The integration of AI with BIM creates powerful visualization and analysis tools that enable construction teams to explore different scenarios, evaluate alternative approaches, and make more informed decisions about construction methods and resource allocation. These capabilities are particularly valuable for complex projects where coordination between multiple trades and systems is critical for success.

Risk Management and Insurance Applications

Construction projects involve numerous risks that can affect cost, schedule, and safety outcomes. AI systems provide sophisticated risk management capabilities by analyzing historical data, current project conditions, and external factors to identify potential risks and suggest mitigation strategies. These systems can assess risks related to weather conditions, labor availability, material costs, regulatory changes, and other factors that could impact project success.

The predictive capabilities of AI risk management systems enable proactive risk mitigation that can prevent problems before they occur or minimize their impact when they do arise. These systems can also support insurance applications by providing objective data about project risks and risk mitigation measures that can inform insurance underwriting and claims processes.

Insurance companies are increasingly using AI systems to assess construction project risks and monitor ongoing projects to identify changes in risk profiles that might affect coverage or premiums. This application of AI technology benefits both construction companies and insurers by providing more accurate risk assessment and enabling more appropriate insurance coverage and pricing.

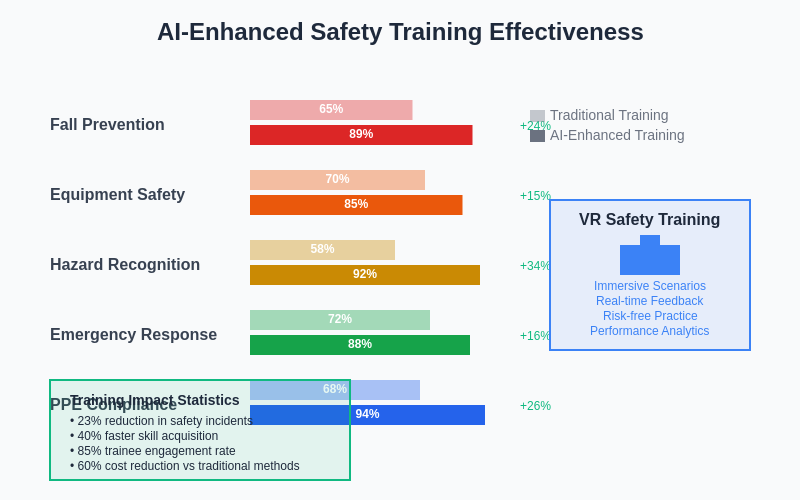

Workforce Training and Skill Development

The construction industry faces ongoing challenges related to workforce development, skill training, and knowledge transfer from experienced workers to newcomers. AI systems are being used to address these challenges through intelligent training programs that can adapt to individual learning needs and provide personalized instruction that improves skill development outcomes.

AI-powered training systems can analyze individual performance data to identify areas where additional training is needed and provide customized instruction that addresses specific skill gaps. These systems can also simulate construction scenarios that allow workers to practice skills and procedures in safe, controlled environments before applying them on actual job sites.

The integration of AI with virtual and augmented reality technologies creates immersive training experiences that can improve skill development while reducing the time and cost associated with traditional training methods. These technologies are particularly valuable for safety training, where workers can experience and learn to respond to dangerous situations without exposure to actual risks.

Future Developments and Industry Transformation

The application of AI in construction continues to evolve rapidly, with new technologies and applications emerging regularly. Future developments are likely to include even more sophisticated predictive capabilities, expanded integration with Internet of Things devices and sensors, and enhanced automation of construction processes through robotics and autonomous systems.

The transformation of the construction industry through AI adoption represents a fundamental shift toward data-driven decision making, predictive management, and intelligent automation that will reshape how construction projects are planned, executed, and delivered. This transformation will require ongoing investment in technology, training, and organizational change management to realize the full benefits of AI capabilities.

Construction companies that embrace AI technologies early and invest in developing the necessary capabilities and expertise will be well-positioned to compete in an increasingly technology-driven industry. The competitive advantages of AI adoption include improved project outcomes, enhanced safety performance, reduced costs, and increased client satisfaction that can differentiate companies in a competitive marketplace.

The continued development of AI technologies promises to address many of the longstanding challenges facing the construction industry while creating new opportunities for innovation, efficiency, and growth. The successful integration of these technologies with traditional construction expertise and practices will define the future of the construction industry and determine which companies thrive in this new technological landscape.

Disclaimer

This article is for informational purposes only and does not constitute professional advice regarding construction technology implementation or safety procedures. The views expressed are based on current understanding of AI technologies and their applications in construction. Readers should conduct their own research and consult with qualified professionals when implementing AI systems in construction projects. The effectiveness of AI technologies may vary depending on specific project requirements, implementation approaches, and organizational capabilities.