The construction industry stands at the precipice of a technological revolution that promises to transform how infrastructure projects are conceived, planned, and executed. At the forefront of this transformation are pioneering companies like Built Robotics and SafeAI, each developing sophisticated autonomous heavy equipment solutions that leverage cutting-edge artificial intelligence to address longstanding challenges in construction efficiency, safety, and precision. These innovations represent more than mere technological advancement; they embody a fundamental shift toward intelligent automation that could reshape the entire construction ecosystem while addressing critical issues such as labor shortages, safety concerns, and productivity demands.

Explore the latest construction technology trends to understand how artificial intelligence is revolutionizing traditional industries and creating new paradigms for autonomous operations. The emergence of construction robotics represents a convergence of multiple technological disciplines, including computer vision, machine learning, sensor fusion, and advanced control systems, all working in harmony to create machines capable of operating with unprecedented autonomy and intelligence in complex construction environments.

The Evolution of Construction Automation

The construction industry has historically been one of the least digitized sectors of the global economy, relying heavily on manual labor and traditional methodologies that have remained largely unchanged for decades. However, the combination of persistent labor shortages, increasing safety requirements, and mounting pressure for improved productivity has created a compelling case for technological innovation. The advent of construction robotics represents a natural evolution of automation technologies that have already transformed manufacturing, logistics, and other industrial sectors.

Built Robotics and SafeAI have emerged as leaders in this transformation by developing sophisticated systems that can operate heavy construction equipment with minimal human intervention. These companies have recognized that successful construction automation requires more than simply replacing human operators with machines; it demands the creation of intelligent systems capable of making complex decisions, adapting to changing conditions, and collaborating effectively with human workers in dynamic construction environments.

The technological foundations underlying modern construction robotics draw from decades of research in autonomous vehicles, robotics, and artificial intelligence. However, the construction environment presents unique challenges that distinguish it from other domains where automation has been successfully implemented. Construction sites are inherently dynamic, with constantly changing layouts, varying terrain conditions, and complex safety requirements that demand sophisticated perception and decision-making capabilities.

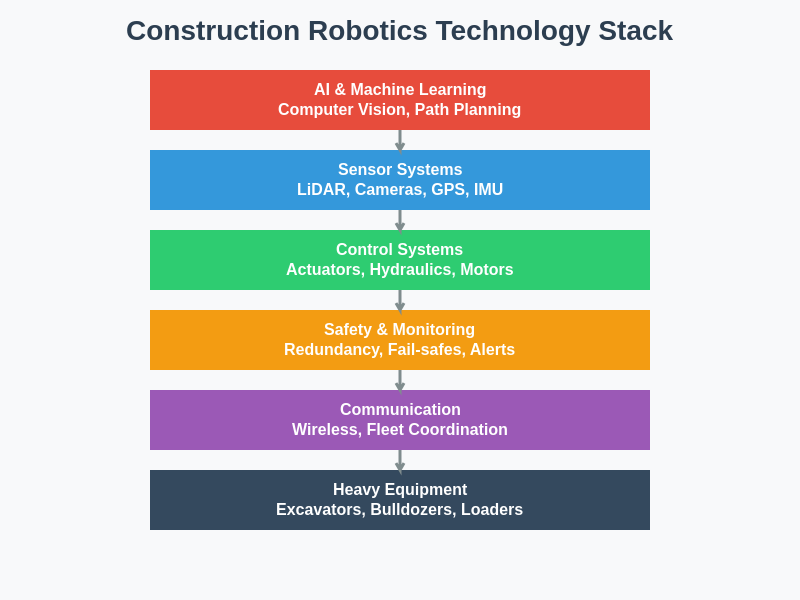

The integration of multiple sensor modalities, including LiDAR, cameras, GPS, and inertial measurement units, enables these autonomous systems to build comprehensive understanding of their operating environment while maintaining precise positioning and navigation capabilities essential for safe and effective operation in construction settings.

Built Robotics: Pioneering Autonomous Earth Moving

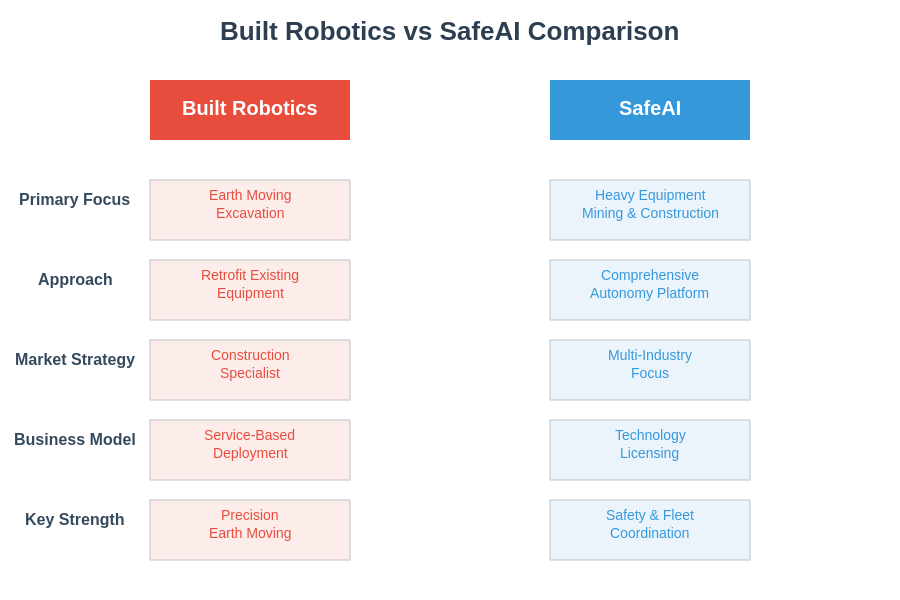

Built Robotics has established itself as a trailblazer in the autonomous construction equipment sector, focusing primarily on earth-moving operations that form the foundation of most construction projects. The company’s approach centers on retrofitting existing heavy equipment with sophisticated AI-powered control systems that can transform conventional excavators, bulldozers, and other earth-moving machines into fully autonomous operators capable of executing complex grading, excavation, and material handling tasks.

The company’s technology stack represents a comprehensive integration of perception, planning, and control systems designed specifically for the demanding requirements of construction environments. Built Robotics has developed proprietary algorithms that enable their systems to understand complex three-dimensional construction plans, interpret terrain conditions, and execute precise earth-moving operations while maintaining strict safety protocols and quality standards.

Experience advanced AI capabilities with Claude for complex reasoning and analysis tasks that require sophisticated understanding of technical systems and industrial applications. The sophistication of Built Robotics’ approach extends beyond simple automation to encompass intelligent decision-making capabilities that allow their systems to adapt to unexpected conditions, optimize operational efficiency, and collaborate effectively with human supervisors and other equipment.

Built Robotics has demonstrated particular strength in addressing the challenges associated with large-scale earthwork projects, where precision and efficiency are paramount. Their systems can operate continuously for extended periods, maintaining consistent quality and productivity levels that often exceed those achievable through traditional manual operation. The company’s focus on retrofit solutions has also made their technology accessible to a broader range of construction companies, allowing existing fleets to be upgraded with autonomous capabilities without requiring complete equipment replacement.

The business model employed by Built Robotics emphasizes service-based deployment rather than direct equipment sales, allowing construction companies to access autonomous capabilities without significant upfront capital investments. This approach has facilitated broader adoption of autonomous construction technology while enabling Built Robotics to maintain close relationships with their customers and continuously refine their systems based on real-world operational feedback.

SafeAI: Comprehensive Heavy Equipment Autonomy

SafeAI has pursued a broader approach to construction automation, developing autonomous solutions for a comprehensive range of heavy construction equipment including mining trucks, wheel loaders, excavators, and specialized industrial vehicles. The company’s technology platform emphasizes safety and reliability, incorporating multiple redundant systems and fail-safe mechanisms designed to ensure safe operation in complex industrial environments where human workers and autonomous machines must coexist.

The technological approach employed by SafeAI reflects a deep understanding of the operational requirements and safety constraints that govern heavy equipment operation in construction and mining environments. Their systems incorporate advanced perception capabilities that enable real-time understanding of dynamic work environments, including the detection and tracking of human workers, other vehicles, and environmental hazards that could impact safe operation.

SafeAI’s commitment to safety extends beyond basic collision avoidance to encompass comprehensive risk assessment and mitigation strategies that consider the complex interactions between autonomous equipment, human workers, and environmental factors. Their systems are designed to operate conservatively in uncertain situations, prioritizing safety over productivity when potential risks are detected.

The company has developed particularly sophisticated solutions for mining and quarrying operations, where the combination of heavy equipment, challenging terrain, and valuable materials creates demanding operational requirements. SafeAI’s systems can coordinate multiple autonomous vehicles working in concert, optimizing traffic flow and operational efficiency while maintaining strict safety protocols.

The comparative analysis reveals distinct strengths and market positioning strategies between these two industry leaders, with SafeAI focusing on comprehensive heavy equipment autonomy across multiple industries while Built Robotics maintains deep specialization in construction earth-moving applications.

Technological Architectures and Approaches

The technological foundations underlying both Built Robotics and SafeAI represent sophisticated integrations of multiple AI disciplines, including computer vision, machine learning, path planning, and control systems. However, each company has developed distinct architectural approaches that reflect their specific market focus and operational priorities.

Built Robotics has emphasized the development of highly specialized systems optimized for specific construction tasks, particularly earth-moving operations that require precise three-dimensional positioning and material handling capabilities. Their technology stack incorporates advanced GPS and inertial navigation systems that enable centimeter-level positioning accuracy, essential for executing complex grading operations and maintaining precise excavation tolerances.

The machine learning components of Built Robotics’ systems focus on terrain understanding and optimal path planning for earth-moving operations. Their algorithms can analyze construction plans, assess current site conditions, and generate efficient operational sequences that minimize material handling while maximizing productivity. The company has invested heavily in developing robust perception systems capable of operating effectively in dusty, cluttered construction environments where traditional computer vision approaches often struggle.

SafeAI’s technological architecture reflects their broader market focus, incorporating modular components that can be adapted to different types of heavy equipment and operational requirements. Their emphasis on safety has led to the development of comprehensive sensor fusion systems that combine multiple perception modalities to create redundant situational awareness capabilities.

The control systems developed by SafeAI incorporate sophisticated decision-making algorithms that can assess risk in real-time and adjust operational parameters to maintain safe operation under varying conditions. Their systems are designed to handle the complex coordination requirements associated with multi-vehicle operations, enabling fleets of autonomous equipment to work together efficiently while maintaining safe separation distances and communication protocols.

Leverage Perplexity’s research capabilities for comprehensive analysis of emerging technologies and market trends that shape the future of autonomous systems and industrial automation. The integration of real-time research capabilities enhances understanding of rapidly evolving technological landscapes and competitive dynamics.

Market Positioning and Competitive Strategies

The competitive landscape in construction robotics reflects fundamentally different strategic approaches pursued by Built Robotics and SafeAI, each targeting distinct market segments and customer needs within the broader construction and heavy industry ecosystem. These strategic differences extend beyond mere technological capabilities to encompass business models, customer engagement strategies, and long-term vision for market development.

Built Robotics has positioned itself as the specialist leader in autonomous earth-moving, developing deep expertise in the specific requirements and challenges associated with construction excavation, grading, and site preparation operations. This focused approach has enabled the company to develop highly optimized solutions that deliver exceptional performance in their target applications while building strong relationships with construction contractors who specialize in earthwork operations.

The company’s retrofit-focused approach has created a compelling value proposition for construction companies seeking to enhance their existing equipment capabilities without the significant capital expenditure associated with purchasing new autonomous machines. This strategy has facilitated broader market adoption while enabling Built Robotics to work closely with equipment manufacturers and develop partnerships that enhance their market reach and technical capabilities.

SafeAI’s broader market strategy reflects their vision of comprehensive heavy equipment autonomy across multiple industrial sectors, including construction, mining, quarrying, and specialized industrial applications. This diversified approach has enabled the company to develop versatile technology platforms that can be adapted to different operational requirements while spreading development costs across multiple market segments.

The company’s emphasis on safety and reliability has resonated particularly strongly with large industrial operators who prioritize risk management and operational consistency. SafeAI’s systems are designed to meet the stringent safety requirements of mining and heavy industrial operations, where accidents can have catastrophic consequences and regulatory compliance is paramount.

Operational Capabilities and Performance Metrics

The practical implementation of autonomous construction equipment requires careful consideration of operational capabilities, performance metrics, and integration with existing construction workflows. Both Built Robotics and SafeAI have demonstrated significant achievements in translating advanced AI technologies into practical solutions that deliver measurable improvements in construction productivity, safety, and quality.

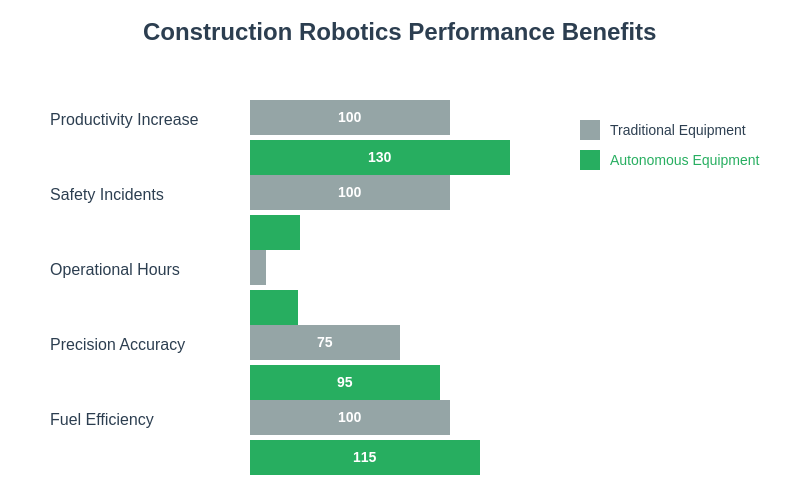

Built Robotics has focused on demonstrating exceptional performance in precision earth-moving operations, achieving levels of accuracy and consistency that often exceed those possible through manual operation. Their systems can maintain grade tolerances within centimeters across large construction sites, reducing the need for rework and improving overall project quality. The company has documented productivity improvements of twenty to thirty percent in typical earth-moving operations, primarily achieved through optimized path planning, consistent operational speeds, and elimination of operator fatigue-related performance variations.

The operational reliability of Built Robotics’ systems has been demonstrated through extended deployment periods where their autonomous equipment has operated continuously for multiple shifts without human intervention. This capability is particularly valuable for large-scale earthwork projects where consistent progress is essential for maintaining project schedules and controlling costs.

SafeAI has demonstrated impressive capabilities in coordinating multiple autonomous vehicles operating simultaneously in complex industrial environments. Their systems can manage traffic flow, optimize loading and hauling operations, and adapt to changing operational conditions while maintaining strict safety protocols. The company has achieved significant improvements in operational efficiency by eliminating idle time, optimizing routing, and enabling twenty-four-hour operations in appropriate environments.

The safety record achieved by SafeAI’s systems represents a particularly significant accomplishment, given the inherent risks associated with heavy equipment operation in industrial environments. Their autonomous systems have demonstrated the ability to operate for extended periods without safety incidents, contributing to improved overall safety performance at deployment sites.

The quantitative comparison of operational performance metrics demonstrates the substantial improvements achieved through autonomous construction equipment deployment, with both companies delivering significant enhancements in productivity, safety, and operational consistency compared to traditional manual operation.

Safety Protocols and Risk Management

Safety considerations represent paramount concerns in the development and deployment of autonomous construction equipment, given the inherent risks associated with heavy machinery operation in complex industrial environments where human workers and autonomous systems must coexist safely. Both Built Robotics and SafeAI have invested heavily in developing comprehensive safety protocols and risk management systems that exceed traditional safety standards while enabling effective autonomous operation.

Built Robotics has implemented multi-layered safety systems that incorporate redundant sensors, fail-safe control mechanisms, and comprehensive monitoring capabilities designed to detect and respond to potential safety hazards in real-time. Their systems are programmed with conservative operational parameters that prioritize safety over productivity when uncertain conditions are encountered, ensuring that autonomous equipment operates within safe boundaries even when faced with unexpected situations.

The company’s safety protocols include comprehensive pre-operational checks, continuous monitoring of system health and performance, and immediate shutdown capabilities that can be activated by human supervisors when necessary. Built Robotics has also developed sophisticated algorithms for detecting and avoiding human workers in construction environments, using multiple sensor modalities to ensure reliable detection and tracking of personnel in various environmental conditions.

SafeAI’s approach to safety reflects their focus on heavy industrial applications where safety requirements are particularly stringent due to the scale and potential consequences of equipment operation. Their systems incorporate multiple independent safety subsystems that can operate autonomously to ensure safe equipment behavior even in the event of primary system failures.

The company has developed particularly sophisticated collision avoidance systems that can assess and respond to complex scenarios involving multiple vehicles, varying terrain conditions, and dynamic environmental factors. SafeAI’s safety protocols extend beyond individual vehicle operation to encompass fleet-level coordination and communication systems that enable safe interaction between multiple autonomous vehicles operating in shared environments.

Integration with Human Workforce

The successful deployment of autonomous construction equipment requires careful consideration of how these systems integrate with existing human workforce structures, operational procedures, and management practices. Both Built Robotics and SafeAI have recognized that effective autonomous construction systems must complement rather than replace human expertise, creating collaborative work environments where human workers and autonomous machines work together to achieve superior outcomes.

Built Robotics has developed operational models that position human supervisors as strategic coordinators and quality managers rather than equipment operators, enabling skilled workers to oversee multiple autonomous machines while focusing on higher-level planning and problem-solving activities. This approach leverages human expertise in areas such as complex decision-making, quality assessment, and adaptive planning while utilizing autonomous systems for repetitive, precision-intensive operations.

The company’s systems are designed to provide comprehensive feedback and status information to human supervisors, enabling effective monitoring and management of autonomous operations. Built Robotics has also implemented intuitive interfaces that allow human operators to easily modify operational parameters, adjust work plans, and intervene when necessary without requiring extensive technical training.

SafeAI’s approach to human-machine collaboration emphasizes the importance of maintaining human oversight and control capabilities while enabling autonomous systems to handle routine operational tasks. Their systems provide detailed operational data and performance metrics that enable human managers to optimize fleet performance, identify improvement opportunities, and ensure compliance with safety and quality standards.

The company has developed training programs and support systems designed to help existing equipment operators transition to supervisory roles, recognizing that successful autonomous deployment requires workforce adaptation rather than replacement. SafeAI’s approach acknowledges the continued importance of human expertise in complex decision-making, emergency response, and quality management while leveraging autonomous capabilities to improve operational efficiency and safety.

Economic Impact and Return on Investment

The economic implications of autonomous construction equipment deployment extend beyond simple labor cost considerations to encompass comprehensive improvements in productivity, quality, safety, and operational efficiency that can deliver significant return on investment for construction companies and industrial operators. Both Built Robotics and SafeAI have documented substantial economic benefits achieved through their autonomous systems, though the specific value propositions vary depending on application requirements and operational contexts.

Built Robotics has demonstrated compelling economic returns through their focus on precision earth-moving operations, where improved accuracy and consistency translate directly into reduced rework costs, faster project completion, and improved quality outcomes. The company’s customers have reported significant reductions in material waste, improved schedule adherence, and enhanced overall project profitability through the deployment of autonomous earth-moving equipment.

The service-based business model employed by Built Robotics has enabled construction companies to access autonomous capabilities without significant upfront capital investments, reducing financial barriers to adoption while providing predictable operational costs. This approach has facilitated broader market adoption while enabling customers to realize immediate productivity benefits without waiting for equipment depreciation or financing arrangements.

SafeAI’s economic value proposition emphasizes the benefits of continuous operation, improved safety performance, and optimized fleet utilization that can be achieved through autonomous heavy equipment deployment. Their customers have documented significant improvements in operational efficiency, reduced downtime, and enhanced safety performance that translate into measurable economic benefits.

The company’s focus on heavy industrial applications has enabled them to demonstrate particularly compelling returns on investment in environments where equipment utilization rates, safety performance, and operational consistency have direct impacts on overall profitability. SafeAI’s systems have enabled twenty-four-hour operations in appropriate environments, significantly improving asset utilization while reducing per-unit operational costs.

Future Technology Roadmaps

The future development trajectories of both Built Robotics and SafeAI reflect ambitious visions for expanding autonomous capabilities, enhancing system intelligence, and addressing broader segments of the construction and heavy industry markets. These roadmaps encompass technological advancement, market expansion, and ecosystem development strategies that position both companies for continued growth and innovation in the rapidly evolving autonomous systems landscape.

Built Robotics has outlined plans for expanding their autonomous capabilities beyond earth-moving to encompass additional construction operations such as concrete placement, material handling, and specialized construction tasks. The company is investing in advanced AI technologies that will enable their systems to handle increasingly complex construction scenarios while maintaining their focus on precision and reliability.

The company’s future roadmap includes development of enhanced collaboration capabilities that will enable multiple autonomous machines to work together on complex construction projects, sharing information and coordinating activities to optimize overall project efficiency. Built Robotics is also exploring integration with construction management systems and building information modeling platforms to create seamless workflows from design through execution.

SafeAI’s technology roadmap emphasizes continued advancement in safety systems, autonomous intelligence, and fleet coordination capabilities that will enable more sophisticated autonomous operations across diverse industrial applications. The company is developing next-generation perception systems that will provide enhanced environmental understanding and enable operation in increasingly challenging conditions.

The company’s future plans include expansion into new market segments and development of autonomous solutions for specialized industrial applications that require unique capabilities and safety requirements. SafeAI is also investing in advanced analytics and predictive maintenance capabilities that will enable their systems to optimize performance and reliability while reducing operational costs.

Industry Implications and Market Transformation

The emergence of successful autonomous construction equipment solutions represents a watershed moment for the construction industry, with implications that extend far beyond the specific capabilities demonstrated by Built Robotics and SafeAI. These developments signal the beginning of a broader transformation that will reshape how construction projects are planned, executed, and managed while addressing fundamental challenges that have constrained industry growth and innovation.

The demonstrated success of autonomous construction equipment has validated the potential for AI and robotics technologies to address critical industry challenges including labor shortages, safety concerns, and productivity demands. This validation is likely to accelerate investment in construction technology development while encouraging broader adoption of autonomous solutions across diverse construction applications.

The competitive dynamics established by Built Robotics and SafeAI are likely to influence the strategies pursued by traditional construction equipment manufacturers, technology companies, and construction contractors as they seek to capitalize on the opportunities created by autonomous construction technology. This competitive pressure will likely accelerate innovation and drive continued improvement in autonomous capabilities while reducing costs and expanding accessibility.

The successful deployment of autonomous construction equipment also has implications for workforce development, regulatory frameworks, and industry standards that will need to evolve to accommodate the integration of intelligent machines into construction workflows. These changes will require collaboration between technology developers, industry stakeholders, and regulatory bodies to ensure safe and effective adoption of autonomous construction technologies.

The broader implications of construction robotics extend to infrastructure development, project economics, and the fundamental capabilities of the construction industry to address growing infrastructure needs while maintaining high standards of safety, quality, and environmental responsibility. The continued advancement of autonomous construction technology promises to unlock new levels of capability and efficiency that will benefit society through improved infrastructure and enhanced construction industry performance.

Disclaimer

This article is for informational purposes only and does not constitute professional advice. The views expressed are based on publicly available information about Built Robotics and SafeAI and their respective technologies. Readers should conduct their own research and consider their specific requirements when evaluating autonomous construction equipment solutions. The effectiveness and suitability of different autonomous systems may vary depending on specific applications, operational requirements, and regulatory environments.