The field of humanoid robotics has reached a pivotal moment where two technological titans are shaping the future of artificial intelligence and mechanical engineering. Boston Dynamics, with their legendary Atlas robot, and Tesla, with their ambitious Optimus project, represent fundamentally different approaches to creating machines that can walk, work, and interact in human environments. These pioneering efforts are not merely technological demonstrations but represent the vanguard of a transformation that will reshape industries, redefine work, and fundamentally alter how humans interact with intelligent machines in everyday life.

Explore the latest robotics and AI developments to understand how these breakthrough technologies are evolving at an unprecedented pace. The competition between these two approaches to humanoid robotics illuminates different philosophies about artificial intelligence, manufacturing scalability, and the ultimate role that robots will play in society, each offering unique insights into the challenges and opportunities that lie ahead in the robotics revolution.

The Genesis of Modern Humanoid Robotics

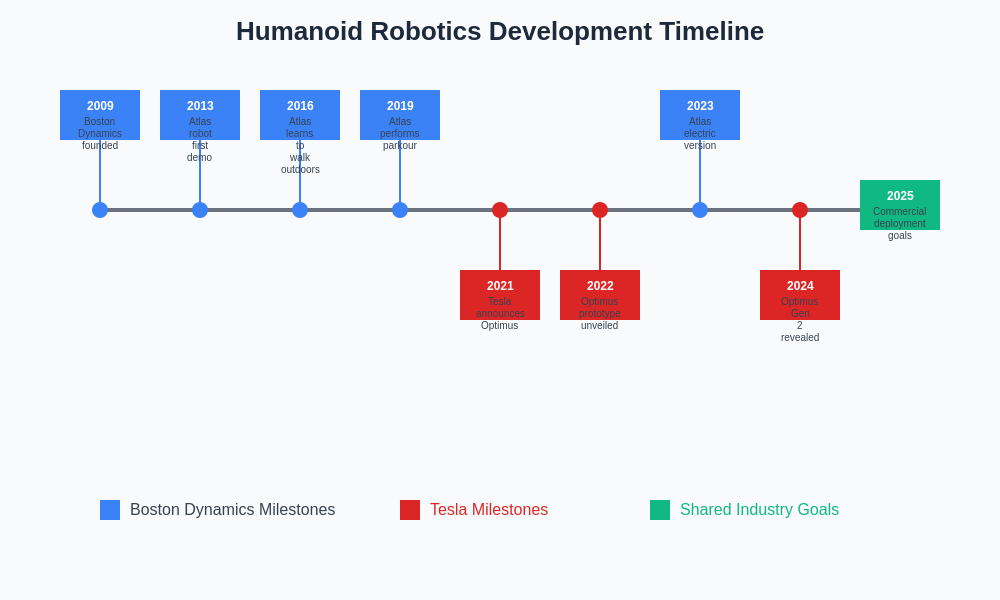

The journey toward creating truly functional humanoid robots has been decades in the making, with both Boston Dynamics and Tesla building upon years of foundational research and development in artificial intelligence, mechanical engineering, and advanced manufacturing. Boston Dynamics emerged from the Massachusetts Institute of Technology with a focus on creating robots capable of navigating complex terrain and performing dynamic movements that closely mimic biological locomotion. Their approach has consistently emphasized the development of sophisticated control systems and mechanical designs that prioritize agility, balance, and adaptability in challenging environments.

Tesla’s entry into humanoid robotics represents a more recent but equally ambitious undertaking, leveraging the company’s extensive experience in electric vehicle manufacturing, battery technology, and artificial intelligence systems developed for autonomous driving. The Optimus project embodies Tesla’s characteristic approach of integrating cutting-edge technology with mass production capabilities, aiming to create humanoid robots that can be manufactured at scale while maintaining advanced functionality and competitive pricing.

The fundamental difference in these approaches reflects broader philosophical divisions in the robotics community about whether to prioritize performance and capability or accessibility and widespread adoption. Boston Dynamics has traditionally focused on pushing the boundaries of what is mechanically and computationally possible, creating robots that demonstrate remarkable capabilities even if they remain expensive and specialized. Tesla, conversely, has approached the challenge with an eye toward eventual mass market deployment, seeking to balance capability with manufacturability and cost-effectiveness.

Atlas: The Pinnacle of Dynamic Robotics

Boston Dynamics’ Atlas robot represents the culmination of decades of research into dynamic locomotion and advanced control systems. Standing approximately six feet tall and weighing around 190 pounds, Atlas demonstrates capabilities that were once considered purely theoretical, including the ability to perform backflips, navigate complex obstacle courses, and maintain balance while being physically disrupted. The robot’s hydraulic actuation system provides the power and precision necessary for these dynamic movements, while its sophisticated sensor suite enables real-time environmental perception and adaptive response to changing conditions.

Discover advanced AI capabilities with Claude for understanding the complex algorithms and neural networks that power modern robotics systems. The artificial intelligence powering Atlas represents a masterful integration of multiple technological domains, including computer vision for environmental mapping, machine learning algorithms for motion planning, and advanced control theory for maintaining stability during complex maneuvers.

The sensor technology integrated into Atlas includes multiple cameras, laser range finders, and inertial measurement units that work in concert to create a comprehensive understanding of the robot’s environment and its position within that space. This sensory information is processed by onboard computers running sophisticated algorithms that can make split-second decisions about foot placement, joint articulation, and balance adjustments necessary for successful navigation through unpredictable terrain.

Atlas’s artificial intelligence system demonstrates remarkable adaptability in its ability to recover from unexpected perturbations, whether caused by external forces or changes in the environment. The robot can adjust its gait pattern in real-time, modify its intended path to avoid obstacles, and even improvise solutions when its planned approach proves inadequate for the task at hand.

Tesla Optimus: Revolutionizing Humanoid Accessibility

Tesla’s Optimus robot represents a fundamentally different approach to humanoid robotics, one that prioritizes practical application and mass manufacturability over pure performance capabilities. Standing approximately five feet eight inches tall and designed to weigh around 125 pounds, Optimus is conceived as a general-purpose humanoid robot capable of performing a wide variety of tasks in industrial, commercial, and eventually residential environments.

The design philosophy behind Optimus reflects Tesla’s automotive manufacturing expertise, incorporating lightweight materials, efficient electric motors, and integrated battery systems that draw heavily from the company’s experience in electric vehicle development. This approach enables Optimus to operate for extended periods without external power sources while maintaining the structural integrity necessary for useful work performance.

Tesla’s artificial intelligence approach for Optimus leverages the same neural network architectures and training methodologies that power the company’s Full Self-Driving technology. This foundation provides Optimus with sophisticated visual processing capabilities, enabling the robot to understand and interpret complex visual scenes, recognize objects and obstacles, and plan appropriate responses to dynamic situations.

The integration of Tesla’s AI systems with Optimus creates unique advantages in terms of learning and adaptation. The robot can benefit from the vast amounts of real-world data collected by Tesla’s fleet of vehicles, providing insights into navigation, object recognition, and decision-making that can be adapted for humanoid robotics applications.

Artificial Intelligence Architectures and Capabilities

The artificial intelligence systems powering these humanoid robots represent some of the most sophisticated implementations of machine learning and neural network technology currently available. Boston Dynamics’ approach to AI focuses heavily on real-time control and dynamic response, utilizing advanced algorithms that can process sensory information and generate appropriate motor commands within milliseconds of detecting environmental changes.

Atlas employs a hierarchical control system that operates at multiple levels, from high-level path planning and goal setting to low-level motor control and balance maintenance. This architecture enables the robot to maintain stable operation while performing complex tasks that require both precision and adaptability. The machine learning components of Atlas’s AI system are continuously refined through extensive testing and simulation, allowing the robot to improve its performance over time.

Tesla’s AI architecture for Optimus is built upon the foundation of neural networks originally developed for autonomous vehicle operation. These systems excel at processing vast amounts of visual and sensory data to create comprehensive understanding of environmental conditions and appropriate responses. The neural networks powering Optimus are designed to handle the complexity of human environments, where objects may be moved, lighting conditions change, and unexpected obstacles appear without warning.

Enhance your AI research with Perplexity to stay informed about the latest developments in neural network architectures and machine learning algorithms that drive modern robotics advancement. The continuous evolution of these AI systems represents one of the most exciting aspects of current humanoid robotics development, with improvements in processing power and algorithmic sophistication enabling increasingly capable and autonomous robot behavior.

Manufacturing Philosophy and Scalability

The approaches taken by Boston Dynamics and Tesla toward manufacturing and scalability reveal fundamental differences in their vision for the future of humanoid robotics. Boston Dynamics has traditionally operated as a research and development organization focused on pushing the boundaries of robotic capability, with manufacturing volumes and costs being secondary considerations to performance and innovation.

This research-focused approach has enabled Boston Dynamics to create robots with extraordinary capabilities, but it has also resulted in extremely high manufacturing costs and limited production volumes. Each Atlas robot represents a significant investment in advanced materials, precision manufacturing, and sophisticated electronic systems that make widespread deployment economically challenging.

Tesla’s manufacturing philosophy for Optimus reflects the company’s automotive industry experience, where success depends on the ability to produce complex products at scale while maintaining quality and controlling costs. The design of Optimus incorporates manufacturing considerations from the earliest stages of development, utilizing materials and construction techniques that can be efficiently scaled to high-volume production.

The potential for mass production represents one of Tesla’s most significant advantages in the humanoid robotics market. If successful, Tesla’s approach could make humanoid robots accessible to a much broader range of applications and customers, potentially accelerating the adoption of robotic assistance across multiple industries and use cases.

Applications and Market Positioning

The different capabilities and design philosophies of Atlas and Optimus naturally lead to different potential applications and market positioning strategies. Boston Dynamics has positioned Atlas primarily as a research platform and demonstration of advanced robotics capabilities, with potential applications in search and rescue operations, hazardous environment exploration, and other specialized tasks that require exceptional agility and adaptability.

Atlas’s ability to navigate complex terrain and perform dynamic movements makes it particularly well-suited for applications where human-like mobility is essential but human presence would be dangerous or impractical. These might include disaster response scenarios, military applications, or industrial environments with significant safety hazards.

Tesla has positioned Optimus as a general-purpose humanoid robot designed for widespread adoption across multiple industries and applications. The initial focus appears to be on manufacturing and industrial applications where repetitive tasks, material handling, and basic assembly operations could benefit from humanoid robotics capabilities.

The broader vision for Optimus extends beyond industrial applications to include potential residential and service applications. Tesla has suggested that Optimus could eventually perform household tasks, provide elderly care assistance, and serve as a general-purpose robotic assistant in various commercial and residential settings.

Technical Performance Comparison

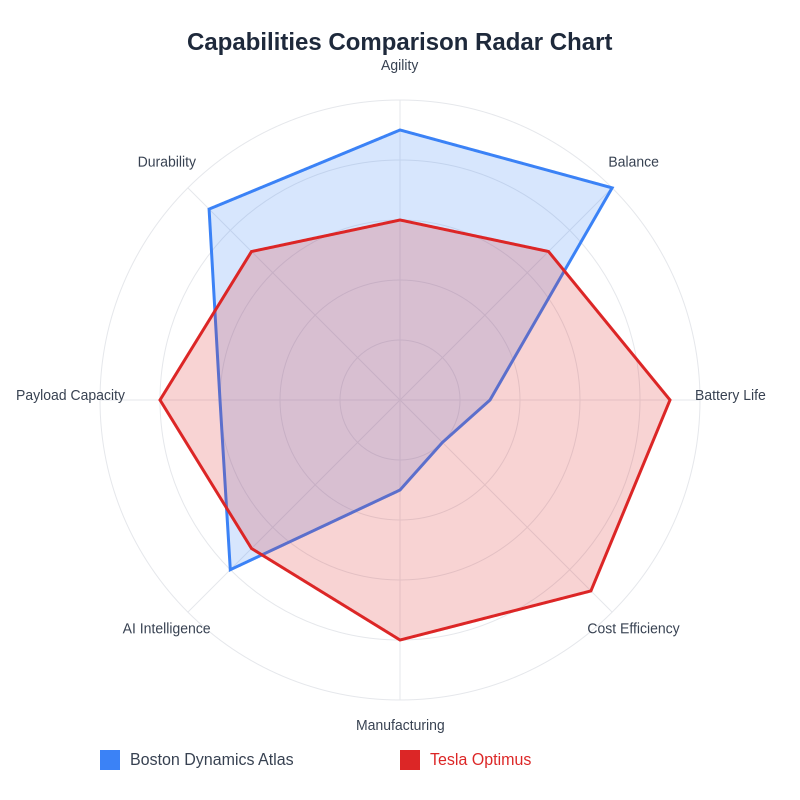

When comparing the technical performance of Atlas and Optimus, it becomes clear that each robot excels in different areas that reflect their respective design priorities and intended applications. Atlas demonstrates superior dynamic capabilities, with the ability to perform complex acrobatic movements, navigate challenging terrain, and recover from significant physical disturbances. These capabilities are enabled by its powerful hydraulic actuation system and sophisticated control algorithms.

Atlas’s sensor suite provides exceptional environmental awareness, enabling the robot to operate effectively in complex and unpredictable environments. The integration of multiple sensing modalities creates redundancy and robustness that enhances the robot’s ability to function reliably in challenging conditions.

Optimus, while perhaps less capable in terms of pure dynamic performance, offers advantages in terms of operational efficiency, battery life, and practical utility for everyday tasks. The robot’s electric actuation system provides quiet operation and energy efficiency that make it more suitable for deployment in human environments.

The artificial intelligence systems powering both robots represent significant achievements in their own right, with Atlas focusing on real-time control and dynamic response while Optimus emphasizes visual processing and task understanding derived from Tesla’s automotive AI development.

The technical specifications reveal fundamental differences in design philosophy, with Atlas prioritizing performance capabilities while Optimus emphasizes efficiency and manufacturability. These contrasting approaches reflect different visions for how humanoid robots will integrate into various applications and market segments.

Economic Implications and Market Impact

The economic implications of successful humanoid robotics development extend far beyond the robotics industry itself, potentially affecting labor markets, manufacturing processes, and the broader economy. The different approaches taken by Boston Dynamics and Tesla represent alternative pathways for how this transformation might unfold.

Boston Dynamics’ focus on high-performance, specialized robots suggests a future where humanoid robotics initially penetrates markets where the value proposition justifies high costs. This might include applications in dangerous or highly specialized environments where human workers face significant risks or where the unique capabilities of advanced robots provide clear economic benefits.

Tesla’s mass-market approach, if successful, could lead to much more widespread adoption of humanoid robotics across a broader range of applications. The potential for lower-cost, mass-produced humanoid robots could accelerate the transformation of manufacturing, logistics, and service industries by making robotic assistance economically viable for smaller organizations and less specialized applications.

The competitive dynamics between these approaches will likely shape the development of the entire humanoid robotics industry, influencing investment priorities, research directions, and regulatory considerations. The success or failure of these different strategies will provide valuable insights into the optimal balance between capability and accessibility in advanced robotics systems.

Future Development Trajectories

The future development of humanoid robotics will likely be influenced by the lessons learned from both the Boston Dynamics and Tesla approaches to robot design and implementation. Each strategy offers unique insights into the challenges and opportunities associated with creating truly functional humanoid robots that can operate effectively in human environments.

Boston Dynamics’ continued focus on advanced capabilities and dynamic performance will likely drive innovations in control systems, mechanical design, and artificial intelligence that benefit the entire robotics community. The research and development efforts behind Atlas continue to push the boundaries of what is mechanically and computationally possible, creating new possibilities for robot functionality and application.

Tesla’s emphasis on manufacturability and cost-effectiveness represents an equally important contribution to the field, demonstrating how advanced robotics technology can be made accessible to broader markets and applications. The success of the Optimus project could prove that sophisticated humanoid robots can be produced at scale without sacrificing essential functionality.

The convergence of these approaches over time seems likely, with high-performance robots eventually becoming more affordable through manufacturing innovations while cost-effective robots gradually gain more sophisticated capabilities through continued technological advancement. This convergence could lead to a future where humanoid robots with both exceptional capabilities and reasonable costs become widely available.

The capabilities analysis demonstrates how each platform excels in different areas, with Atlas showing superior performance in agility and balance while Optimus leads in battery life and cost efficiency. This complementary strength distribution suggests that both approaches address different market needs and application requirements.

Societal and Ethical Considerations

The development of advanced humanoid robotics raises important questions about the societal and ethical implications of creating machines that can perform tasks traditionally associated with human workers. Both Boston Dynamics and Tesla are navigating these considerations as they develop their respective robotics platforms, though their different approaches suggest different perspectives on these challenges.

The potential displacement of human workers by humanoid robots represents one of the most significant societal concerns associated with these technologies. The widespread adoption of capable humanoid robots could affect employment across multiple industries, requiring careful consideration of how society will adapt to these changes and support workers whose roles may be affected by automation.

Privacy and security considerations also become increasingly important as humanoid robots become more capable and widespread. These robots will likely have access to sensitive information about their environments and the people they interact with, requiring robust safeguards to protect privacy and prevent misuse of collected data.

The question of human-robot interaction and the psychological effects of widespread humanoid robot deployment also deserves careful consideration. As these machines become more capable and human-like in their appearance and behavior, society will need to develop new frameworks for understanding and regulating these interactions.

Integration with Broader AI Ecosystems

Both Atlas and Optimus represent components of broader artificial intelligence ecosystems that extend far beyond the robots themselves. Boston Dynamics’ work on Atlas contributes to a deeper understanding of dynamic control, environmental perception, and real-time decision-making that has applications across multiple domains of artificial intelligence and robotics.

Tesla’s development of Optimus leverages and contributes to the company’s broader AI ecosystem, which includes autonomous driving technology, energy management systems, and manufacturing automation. This integration creates synergies that can accelerate development across multiple product lines while providing Optimus with access to vast amounts of real-world data and proven AI technologies.

The interconnected nature of these AI ecosystems suggests that the future of humanoid robotics will be closely tied to developments in other areas of artificial intelligence, including natural language processing, computer vision, and machine learning. Success in humanoid robotics will likely depend on the ability to integrate multiple AI technologies into cohesive systems that can operate effectively in complex, real-world environments.

Technological Convergence and Innovation

The competition between Boston Dynamics and Tesla in humanoid robotics is driving rapid innovation across multiple technological domains, from advanced materials and manufacturing techniques to artificial intelligence and control systems. This competitive environment is accelerating the pace of development and pushing both organizations to explore new approaches and solutions.

The sharing of research findings and technological insights within the broader robotics community ensures that innovations developed by either organization can contribute to the advancement of the field as a whole. This collaborative aspect of technological development helps to maximize the societal benefits of humanoid robotics research while maintaining competitive incentives for continued innovation.

The convergence of different technological approaches and philosophies in humanoid robotics is likely to produce hybrid solutions that combine the best aspects of both high-performance and mass-market strategies. These hybrid approaches could lead to the development of humanoid robots that offer both exceptional capabilities and reasonable costs, making advanced robotics technology accessible to a much broader range of applications and users.

The historical development timeline illustrates the different trajectories taken by Boston Dynamics and Tesla, with Boston Dynamics building capabilities over more than a decade while Tesla has rapidly accelerated development through leveraging existing automotive and AI technologies. This timeline perspective reveals how different development strategies can lead to breakthrough innovations in humanoid robotics.

The future of humanoid robotics will ultimately be shaped by the continued evolution of artificial intelligence, manufacturing technology, and our understanding of how to create machines that can work effectively alongside humans in complex environments. The pioneering efforts of Boston Dynamics and Tesla provide valuable insights into the challenges and opportunities that lie ahead in this transformation, offering different but equally important contributions to the development of truly functional humanoid robots.

Disclaimer

This article is for informational purposes only and does not constitute investment or technical advice. The views expressed are based on publicly available information about robotics technologies and their potential applications. Readers should conduct their own research and consider their specific requirements when evaluating robotics solutions. The capabilities and performance characteristics of robotics systems may vary depending on specific configurations, environmental conditions, and application requirements. Future developments in robotics technology may differ significantly from current projections and expectations.