The convergence of Industrial Internet of Things (IoT) and artificial intelligence has fundamentally transformed manufacturing operations, creating unprecedented opportunities for operational excellence through predictive maintenance and autonomous quality control systems. This technological revolution represents a paradigm shift from reactive maintenance strategies and manual quality inspection processes toward proactive, data-driven approaches that maximize equipment uptime, minimize operational costs, and ensure consistent product quality across complex manufacturing environments.

The integration of AI-powered analytics with Industrial IoT infrastructure has enabled manufacturers to harness vast amounts of real-time operational data, transforming raw sensor information into actionable insights that drive strategic decision-making and optimize production processes. Stay updated with the latest AI trends in industrial applications to understand how emerging technologies continue to reshape manufacturing landscapes and create new possibilities for operational enhancement and competitive advantage.

The Foundation of Industrial IoT AI Systems

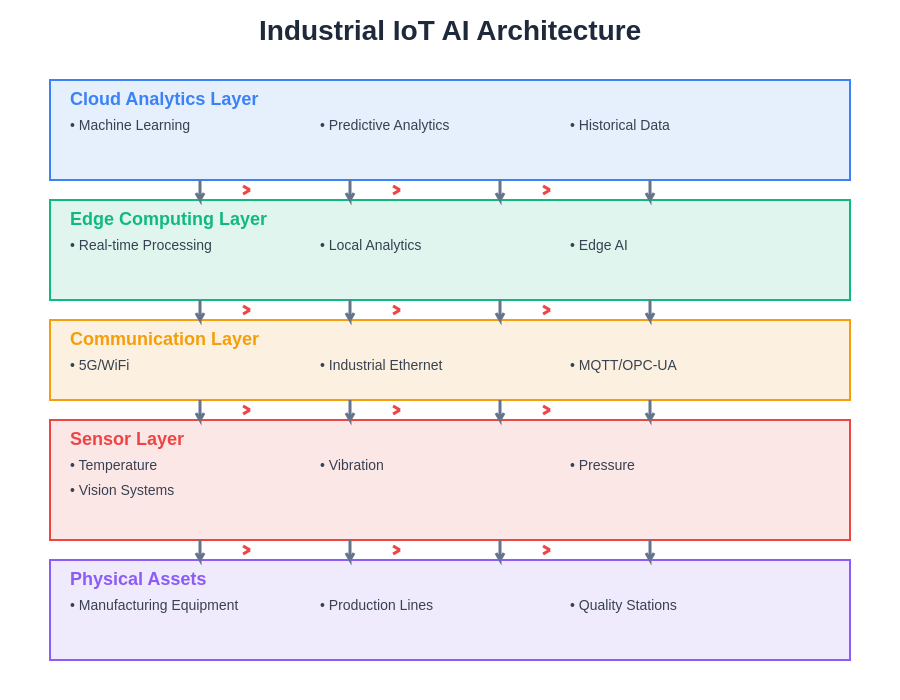

Industrial IoT AI systems represent a sophisticated fusion of hardware sensors, communication networks, edge computing capabilities, and advanced machine learning algorithms that work in concert to monitor, analyze, and optimize manufacturing operations in real-time. These comprehensive systems deploy thousands of interconnected sensors throughout manufacturing facilities, collecting continuous streams of data on equipment performance, environmental conditions, product quality parameters, and operational metrics that provide unprecedented visibility into every aspect of the production process.

The architectural complexity of these systems requires careful integration of multiple technological layers, including sensor networks that capture physical measurements, communication protocols that ensure reliable data transmission, edge computing platforms that enable real-time processing, and cloud-based analytics engines that perform sophisticated pattern recognition and predictive modeling. This multi-layered approach ensures that critical operational decisions can be made autonomously at the point of need while simultaneously feeding comprehensive data sets to centralized intelligence systems that optimize overall facility performance.

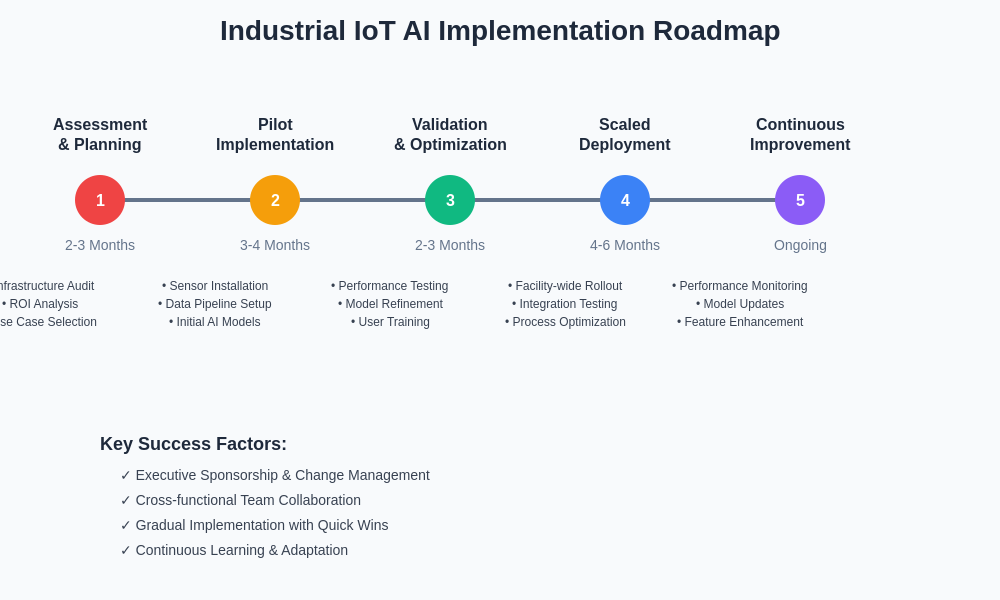

The scalability and flexibility of modern Industrial IoT AI platforms enable manufacturers to implement solutions that grow with their operational needs, starting with pilot deployments in critical areas and expanding to comprehensive facility-wide implementations that encompass every aspect of the manufacturing process. This gradual deployment approach allows organizations to validate the technology’s effectiveness while building internal expertise and refining operational procedures that maximize the return on investment from these sophisticated systems.

The interconnected nature of modern industrial systems creates complex data relationships that require sophisticated AI algorithms to understand and optimize, demonstrating how multiple technological components work together to create intelligent manufacturing environments that continuously improve their own performance through machine learning and adaptive optimization.

Revolutionizing Predictive Maintenance Strategies

Predictive maintenance represents one of the most impactful applications of Industrial IoT AI, transforming traditional time-based maintenance schedules into condition-based strategies that optimize equipment performance while minimizing downtime and maintenance costs. Advanced machine learning algorithms analyze continuous streams of vibration data, temperature measurements, acoustic signatures, and operational parameters to identify subtle patterns that indicate developing equipment issues long before they result in catastrophic failures or unplanned downtime events.

The sophistication of modern predictive maintenance systems extends beyond simple threshold monitoring to incorporate complex pattern recognition algorithms that understand the unique operational signatures of individual machines and production lines. These AI-powered systems learn the normal operational patterns for each piece of equipment, establishing baseline performance profiles that enable the detection of anomalies that might indicate developing problems such as bearing wear, misalignment issues, lubrication deficiencies, or component degradation that could lead to costly failures if left unaddressed.

Explore advanced AI capabilities with Claude to understand how sophisticated reasoning and analysis can enhance predictive maintenance algorithms and improve the accuracy of failure prediction models. The integration of multiple data sources and advanced analytics enables maintenance teams to transition from reactive firefighting approaches to proactive maintenance strategies that maximize equipment availability while optimizing maintenance resource allocation and operational costs.

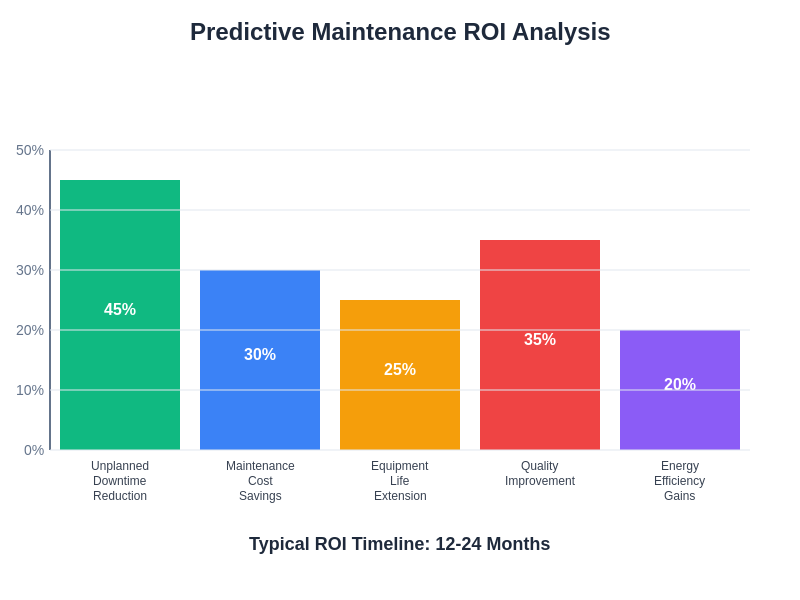

The economic impact of effective predictive maintenance implementation is substantial, with leading manufacturers reporting reductions in unplanned downtime of thirty to fifty percent, maintenance cost savings of twenty to thirty percent, and significant improvements in overall equipment effectiveness that directly translate to increased production capacity and improved profitability. These benefits compound over time as AI systems continuously learn from operational data and refine their predictive capabilities, becoming increasingly accurate at identifying potential issues and optimizing maintenance scheduling to minimize operational disruption.

Autonomous Quality Control and Inspection Systems

Quality control has evolved from manual inspection processes and statistical sampling approaches to comprehensive automated systems that inspect every product using computer vision, advanced sensors, and machine learning algorithms that ensure consistent quality standards while identifying defects and variations that human inspectors might miss. These AI-powered quality control systems operate at production speeds, providing real-time feedback that enables immediate process adjustments and prevents the production of defective products that would require costly rework or result in customer quality issues.

The sophistication of modern quality control AI extends beyond simple pass-fail determinations to include detailed analysis of product characteristics, dimensional measurements, surface quality assessments, and functional testing that provides comprehensive quality documentation for every manufactured item. Advanced computer vision systems can detect microscopic defects, measure critical dimensions with sub-millimeter precision, and identify subtle variations in color, texture, or finish that indicate process variations or material quality issues that require immediate attention.

Machine learning algorithms continuously improve their inspection capabilities by analyzing the correlation between detected variations and downstream quality issues, enabling these systems to become increasingly sensitive to potential problems while reducing false positive rates that can disrupt production operations. The ability to learn from historical quality data and process parameters enables AI systems to identify root causes of quality issues and recommend process adjustments that prevent defects from occurring rather than simply detecting them after they have been produced.

The integration of quality control AI with production control systems enables real-time process optimization that maintains product quality within tight specifications while maximizing production efficiency. When quality variations are detected, these systems can automatically adjust process parameters, alert operators to potential issues, or temporarily halt production to prevent the manufacture of defective products, ensuring that quality standards are maintained without compromising production throughput or efficiency.

Real-Time Process Optimization and Control

Industrial IoT AI systems excel at real-time process optimization by continuously monitoring hundreds of process variables and automatically adjusting operational parameters to maintain optimal performance across complex manufacturing operations. These sophisticated control systems use advanced algorithms to understand the complex relationships between input variables, process conditions, and output quality, enabling autonomous optimization that improves efficiency, reduces waste, and maintains consistent product quality despite variations in raw materials, environmental conditions, or equipment performance.

The implementation of real-time optimization requires sophisticated edge computing capabilities that can process vast amounts of sensor data and execute control decisions within milliseconds of detecting changes in operating conditions. This rapid response capability is essential for maintaining stable process conditions in dynamic manufacturing environments where small variations can cascade into significant quality or efficiency issues if not addressed immediately through appropriate control adjustments.

Discover comprehensive AI research capabilities with Perplexity to explore the latest developments in process optimization algorithms and real-time control systems that continue to advance the capabilities of Industrial IoT AI platforms. The continuous evolution of these technologies enables manufacturers to achieve increasingly sophisticated levels of process control and optimization that were previously impossible with traditional control systems.

Advanced optimization algorithms consider multiple objectives simultaneously, balancing factors such as production throughput, energy consumption, material utilization, quality parameters, and equipment wear to identify optimal operating points that maximize overall operational efficiency. This multi-objective optimization approach ensures that improvements in one area do not negatively impact other critical performance metrics, maintaining the delicate balance required for optimal manufacturing operations.

Energy Management and Sustainability Optimization

The environmental and economic benefits of Industrial IoT AI extend to comprehensive energy management systems that optimize power consumption, reduce waste, and minimize the environmental impact of manufacturing operations. These intelligent systems monitor energy usage patterns across entire facilities, identifying opportunities for optimization, predicting energy demand, and automatically adjusting operations to take advantage of favorable energy pricing or grid conditions while maintaining production schedules and quality requirements.

Advanced energy management AI can coordinate the operation of multiple energy-consuming systems, such as HVAC equipment, production machinery, and facility lighting, to minimize overall energy consumption while maintaining optimal operating conditions for manufacturing processes. This coordinated approach to energy management can result in significant cost savings and environmental benefits without compromising production capacity or product quality, demonstrating how AI can simultaneously improve economic and environmental performance.

The integration of renewable energy sources and energy storage systems with Industrial IoT AI enables manufacturers to optimize their energy mix, reducing dependence on grid electricity and minimizing carbon footprints while maintaining reliable power supply for critical manufacturing operations. These systems can predict energy production from renewable sources, optimize energy storage utilization, and coordinate production schedules to maximize the use of clean energy sources whenever possible.

Predictive energy management capabilities enable manufacturers to anticipate energy demand fluctuations and proactively adjust operations to avoid peak demand charges, participate in demand response programs, and take advantage of time-of-use pricing structures that can significantly reduce overall energy costs. This proactive approach to energy management represents a significant advancement over traditional reactive energy management strategies that simply respond to current conditions rather than anticipating future needs.

The financial benefits of implementing comprehensive Industrial IoT AI systems extend far beyond simple cost savings, creating value through improved operational efficiency, enhanced product quality, reduced environmental impact, and increased manufacturing flexibility that enables organizations to respond more effectively to changing market conditions and customer requirements.

Supply Chain Integration and Optimization

Industrial IoT AI systems are increasingly being integrated with supply chain management platforms to create end-to-end visibility and optimization capabilities that extend beyond individual manufacturing facilities to encompass entire supply networks. These integrated systems can predict supply chain disruptions, optimize inventory levels, coordinate production schedules across multiple facilities, and automatically adjust procurement strategies based on real-time demand forecasts and production capacity assessments.

The ability to share real-time production data and quality metrics with suppliers and customers creates opportunities for collaborative optimization that benefits all participants in the supply chain. Suppliers can receive advance notice of material requirements and quality specifications, enabling them to optimize their own operations and ensure timely delivery of materials that meet exact specifications. Customers can receive real-time updates on production progress and quality metrics, enabling better planning and coordination of their own operations.

Advanced supply chain AI can identify potential bottlenecks and disruptions before they impact production operations, enabling proactive measures such as alternative supplier activation, inventory repositioning, or production schedule adjustments that minimize the impact of supply chain disruptions. This predictive capability is particularly valuable in today’s volatile global supply chain environment where disruptions can have cascading effects throughout entire manufacturing networks.

The integration of blockchain technology with Industrial IoT AI enables secure, transparent tracking of materials and products throughout the supply chain, providing complete traceability and enabling rapid response to quality issues or safety concerns. This comprehensive tracking capability enhances quality control, supports regulatory compliance, and enables more effective recall management when necessary.

Workforce Integration and Human-AI Collaboration

The successful implementation of Industrial IoT AI requires careful consideration of workforce integration and the development of human-AI collaboration models that leverage the strengths of both human expertise and artificial intelligence capabilities. Rather than replacing human workers, these systems are designed to augment human capabilities, providing workers with real-time insights, predictive alerts, and decision support tools that enhance their effectiveness and enable them to focus on higher-value activities that require human judgment and creativity.

Training and development programs are essential for ensuring that workers can effectively collaborate with AI systems, understanding how to interpret AI-generated insights, respond to automated alerts, and override AI decisions when human judgment indicates that alternative actions are appropriate. This human-in-the-loop approach ensures that AI systems enhance rather than replace human expertise while providing safeguards against automated decisions that might not account for unique circumstances or contextual factors that are apparent to experienced operators.

The user interface design for Industrial IoT AI systems must balance comprehensive information presentation with usability and clarity, ensuring that workers can quickly understand system status, identify issues requiring attention, and take appropriate actions without being overwhelmed by excessive data or complex interfaces. Mobile and wearable technologies enable workers to receive real-time updates and alerts regardless of their location within the facility, ensuring that critical information reaches the right people at the right time.

Continuous feedback mechanisms enable workers to provide input on AI system performance, report false alarms or missed detections, and suggest improvements based on their operational experience. This feedback is essential for continuous improvement of AI algorithms and ensures that these systems remain aligned with practical operational requirements and worker expertise.

Cybersecurity and Data Protection Considerations

The interconnected nature of Industrial IoT AI systems creates new cybersecurity challenges that must be addressed through comprehensive security frameworks that protect both operational technology and information technology systems. These security considerations include secure device authentication, encrypted data transmission, network segmentation, access control, and continuous monitoring for potential security threats that could compromise manufacturing operations or sensitive business information.

The implementation of zero-trust security models ensures that every device, user, and data transfer is verified and authorized before being granted access to critical systems or information. This approach is particularly important in Industrial IoT environments where compromised devices could potentially disrupt production operations or provide unauthorized access to sensitive manufacturing processes and business intelligence.

Edge computing security requires special attention because edge devices often operate in environments with limited physical security and may have restricted capabilities for implementing comprehensive security measures. Secure boot processes, hardware security modules, and regular security updates are essential for maintaining the integrity of edge computing systems that process sensitive operational data and control critical manufacturing processes.

Data privacy and compliance considerations are increasingly important as Industrial IoT AI systems collect and process vast amounts of operational data that may include sensitive business information, personal data, or proprietary manufacturing processes. Compliance with regulations such as GDPR, industry-specific data protection requirements, and export control regulations requires careful attention to data handling, storage, and sharing practices throughout the entire Industrial IoT AI ecosystem.

Future Directions and Emerging Technologies

The future evolution of Industrial IoT AI promises even more sophisticated capabilities through the integration of emerging technologies such as 5G communications, edge AI processing, digital twins, augmented reality interfaces, and quantum computing applications that will enable new levels of operational optimization and manufacturing intelligence. These advancing technologies will enable more responsive systems, more accurate predictions, and more comprehensive optimization across increasingly complex manufacturing networks.

Digital twin technology represents a particularly promising development that creates virtual replicas of physical manufacturing assets and processes, enabling sophisticated simulation, optimization, and testing capabilities that can predict the impact of changes before they are implemented in physical systems. These digital twins continuously learn from real-world operational data, becoming increasingly accurate representations that enable more effective optimization and more reliable predictions of system behavior under various operating conditions.

The integration of augmented reality with Industrial IoT AI will enable new forms of human-machine interaction that provide workers with contextual information, visual guidance, and real-time data overlays that enhance their ability to understand complex systems and respond effectively to operational requirements. This technology will be particularly valuable for maintenance activities, quality inspection, and training applications where visual information can significantly enhance worker effectiveness.

Artificial intelligence capabilities will continue to evolve toward more sophisticated reasoning, autonomous decision-making, and self-improving systems that can adapt to changing conditions, learn from new situations, and optimize their own performance without requiring constant human supervision. These advancing AI capabilities will enable Industrial IoT systems to handle increasingly complex operational challenges while maintaining high levels of reliability and safety.

The systematic implementation of Industrial IoT AI technologies requires careful planning, phased deployment, and continuous optimization to ensure successful adoption and maximum return on investment, demonstrating how organizations can effectively transition from traditional manufacturing approaches to AI-enhanced operations that deliver sustained competitive advantages.

Economic Impact and Return on Investment

The economic benefits of Industrial IoT AI implementation extend far beyond simple cost reduction to include revenue enhancement through improved product quality, increased production capacity, reduced time-to-market for new products, and enhanced customer satisfaction through more reliable delivery and quality performance. Leading manufacturers report return on investment periods of twelve to twenty-four months for comprehensive Industrial IoT AI implementations, with ongoing benefits that continue to grow as systems mature and optimization capabilities improve.

The quantification of Industrial IoT AI benefits requires comprehensive measurement systems that track multiple performance indicators including equipment effectiveness, quality metrics, energy consumption, maintenance costs, safety performance, and customer satisfaction scores. This multi-dimensional approach to benefit measurement ensures that the full value of Industrial IoT AI implementation is captured and enables continuous optimization of system performance and return on investment.

Cost-benefit analysis must consider both direct costs such as hardware, software, and implementation services, as well as indirect costs including training, organizational change management, and ongoing system maintenance and optimization. The most successful implementations balance these costs against both quantifiable benefits such as reduced downtime and maintenance costs, as well as strategic benefits such as improved competitive positioning and enhanced capability to respond to market changes.

Long-term value creation from Industrial IoT AI extends beyond operational improvements to include enhanced innovation capabilities, improved risk management, and increased organizational agility that enables more effective response to changing market conditions and customer requirements. These strategic benefits often exceed the direct operational benefits and justify continued investment in advancing Industrial IoT AI capabilities.

Implementation Best Practices and Strategic Considerations

Successful Industrial IoT AI implementation requires comprehensive planning that addresses technical, organizational, and strategic considerations to ensure that these sophisticated systems deliver maximum value while minimizing implementation risks and operational disruption. The most effective approaches begin with pilot implementations in specific areas where benefits can be clearly demonstrated and lessons learned can inform broader deployment strategies.

Change management is a critical success factor that requires extensive communication, training, and support to ensure that workers understand the benefits of Industrial IoT AI systems and are prepared to work effectively with these new technologies. Resistance to change can significantly impact implementation success, making it essential to involve workers in the planning process and demonstrate clear benefits that enhance rather than threaten their roles and responsibilities.

Technical infrastructure requirements must be carefully assessed and upgraded as necessary to support the communication, computing, and storage requirements of comprehensive Industrial IoT AI systems. This includes evaluation of network capacity, data storage capabilities, cybersecurity infrastructure, and integration requirements with existing manufacturing execution systems and enterprise resource planning platforms.

Vendor selection and partnership strategies are crucial for ensuring access to the specialized expertise and ongoing support required for successful Industrial IoT AI implementation and optimization. The most effective approaches involve partnerships with technology providers who offer comprehensive solutions, proven implementation methodologies, and long-term support capabilities that ensure continued system effectiveness and evolution.

Disclaimer

This article is for informational purposes only and does not constitute professional advice. The implementation of Industrial IoT AI systems involves complex technical, operational, and strategic considerations that require careful evaluation by qualified professionals. Readers should conduct thorough research and consult with appropriate experts before making implementation decisions. The effectiveness and benefits of Industrial IoT AI systems may vary significantly depending on specific operational requirements, existing infrastructure, and implementation quality.