The manufacturing industry stands at the precipice of a technological revolution that promises to fundamentally reshape how products are conceived, produced, and delivered to global markets. Artificial intelligence has emerged as the cornerstone of this transformation, particularly in the critical areas of predictive maintenance and quality control, where the convergence of machine learning algorithms, sensor technologies, and data analytics is creating unprecedented opportunities for operational excellence and competitive advantage.

Explore the latest AI trends transforming industries to understand how manufacturing companies worldwide are leveraging cutting-edge technologies to optimize their production processes. The integration of AI into manufacturing operations represents more than a mere technological upgrade; it constitutes a paradigm shift that is redefining the fundamental principles of industrial production and establishing new benchmarks for efficiency, reliability, and quality assurance.

The Evolution of Smart Manufacturing

The journey toward AI-driven manufacturing has been marked by several pivotal technological developments that have collectively enabled the current revolution in industrial operations. Traditional manufacturing systems relied heavily on scheduled maintenance intervals and manual quality inspections, approaches that often resulted in unexpected equipment failures, production delays, and inconsistent product quality. The advent of the Industrial Internet of Things (IIoT) created the foundation for continuous data collection from manufacturing equipment, while advances in machine learning algorithms provided the analytical capabilities necessary to extract actionable insights from this vast quantity of operational data.

Modern smart manufacturing environments are characterized by interconnected systems that continuously monitor equipment performance, environmental conditions, and production metrics through an extensive network of sensors, cameras, and monitoring devices. This comprehensive data collection infrastructure enables AI systems to develop sophisticated models of normal operational behavior and identify subtle deviations that may indicate impending equipment failures or quality issues. The result is a manufacturing environment that operates with unprecedented visibility into operational status and predictive capabilities that enable proactive rather than reactive management approaches.

Predictive Maintenance: Preventing Failures Before They Occur

Predictive maintenance represents one of the most transformative applications of AI in manufacturing environments, offering the potential to dramatically reduce unplanned downtime while optimizing maintenance costs and extending equipment lifespan. Traditional maintenance approaches typically follow either reactive strategies that address failures after they occur or preventive schedules that perform maintenance based on predetermined time intervals regardless of actual equipment condition. Both approaches suffer from significant limitations, including unexpected failures that disrupt production schedules and unnecessary maintenance activities that consume resources without providing proportional benefits.

AI-powered predictive maintenance systems fundamentally transform this paradigm by continuously analyzing equipment condition data to identify patterns and anomalies that indicate developing problems before they result in failures. These systems utilize sophisticated machine learning algorithms to establish baseline patterns for normal equipment operation and continuously monitor for deviations that may signal impending issues. The algorithms can detect subtle changes in vibration patterns, temperature fluctuations, acoustic signatures, and performance metrics that human operators might miss or dismiss as insignificant variations.

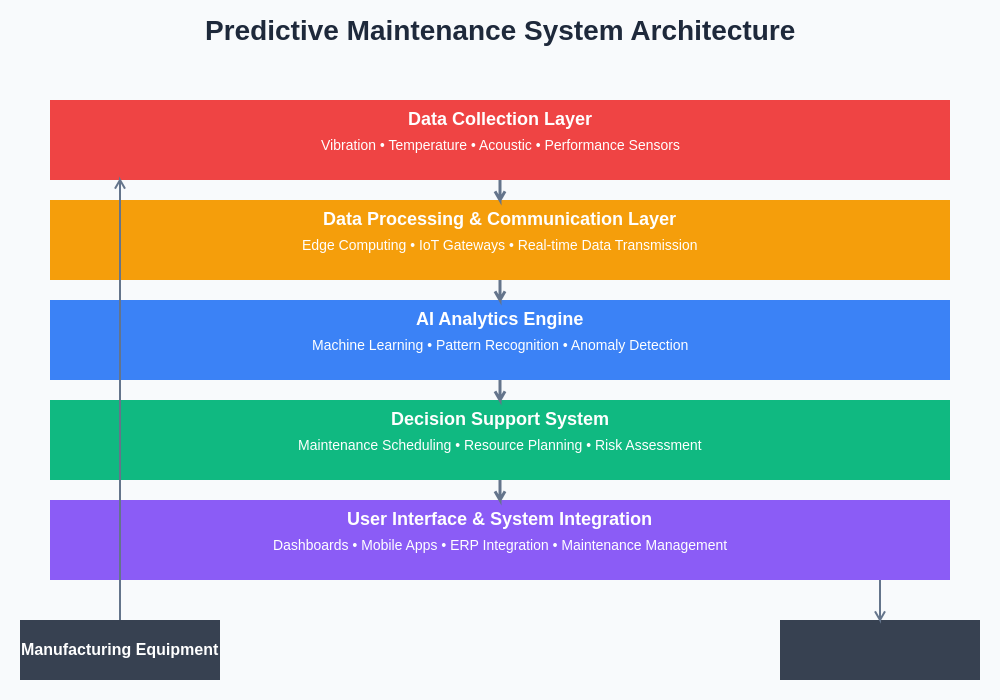

The implementation of predictive maintenance systems involves the deployment of various sensor technologies including accelerometers for vibration monitoring, thermal sensors for temperature analysis, acoustic sensors for sound pattern recognition, and performance monitoring systems that track operational parameters such as pressure, flow rates, and energy consumption. This comprehensive monitoring infrastructure generates enormous volumes of data that AI systems process in real-time to identify trends, correlations, and anomalies that indicate developing maintenance issues.

The architecture of modern predictive maintenance systems demonstrates the sophisticated integration of data collection, processing, and analysis capabilities that enable proactive maintenance strategies. This interconnected approach ensures that maintenance decisions are based on actual equipment condition rather than arbitrary schedules or reactive responses to failures.

Experience advanced AI capabilities with Claude for developing sophisticated predictive models and analytical frameworks that can transform manufacturing operations. The combination of comprehensive data collection and intelligent analysis creates opportunities for maintenance optimization that were previously impossible to achieve through conventional approaches.

Advanced Quality Control Through Machine Vision

Quality control has been revolutionized through the application of AI-powered machine vision systems that can inspect products with greater speed, consistency, and accuracy than traditional manual inspection methods. These systems utilize sophisticated image processing algorithms and deep learning models to identify defects, measure dimensions, verify assembly completeness, and ensure compliance with quality standards across diverse manufacturing applications. The implementation of AI-driven quality control systems has enabled manufacturers to achieve defect detection rates that exceed human inspection capabilities while simultaneously increasing inspection speed and reducing labor costs.

Machine vision systems for quality control typically incorporate high-resolution cameras, specialized lighting systems, and advanced image processing software that can analyze product characteristics at microscopic levels of detail. These systems can detect surface defects such as scratches, dents, discoloration, and contamination, as well as dimensional variations that may affect product functionality or aesthetic appeal. More sophisticated systems can perform complex inspections such as verifying the correct assembly of multi-component products, ensuring proper alignment of components, and confirming the presence and correct positioning of small parts or features.

The learning capabilities of AI-powered quality control systems enable continuous improvement in defect detection accuracy and the ability to adapt to new product variations or quality requirements without extensive reprogramming. These systems can learn from inspection results, operator feedback, and downstream quality data to refine their detection algorithms and reduce false positive rates while maintaining high sensitivity to actual defects. This adaptive capability is particularly valuable in manufacturing environments with frequent product changes or evolving quality standards.

Real-Time Process Optimization

The integration of AI into manufacturing processes extends beyond maintenance and quality control to encompass comprehensive process optimization that continuously adjusts operational parameters to maximize efficiency, minimize waste, and ensure consistent product quality. These systems analyze real-time data from across the production line to identify opportunities for improvement and automatically implement adjustments that optimize performance without human intervention. The result is manufacturing processes that operate at peak efficiency while maintaining flexibility to adapt to changing conditions or requirements.

Real-time process optimization systems utilize machine learning algorithms to model the complex relationships between input variables such as raw material properties, environmental conditions, and equipment settings, and output variables such as product quality, production rate, and resource consumption. These models enable the systems to predict the impact of parameter adjustments and automatically implement changes that improve overall performance. The continuous learning capabilities of these systems ensure that optimization strategies evolve and improve over time as more data becomes available and operating conditions change.

The implementation of real-time optimization systems requires sophisticated data integration capabilities that can collect and process information from diverse sources including production equipment, environmental sensors, quality control systems, and enterprise resource planning systems. This comprehensive data integration enables holistic optimization approaches that consider the entire production system rather than optimizing individual components in isolation.

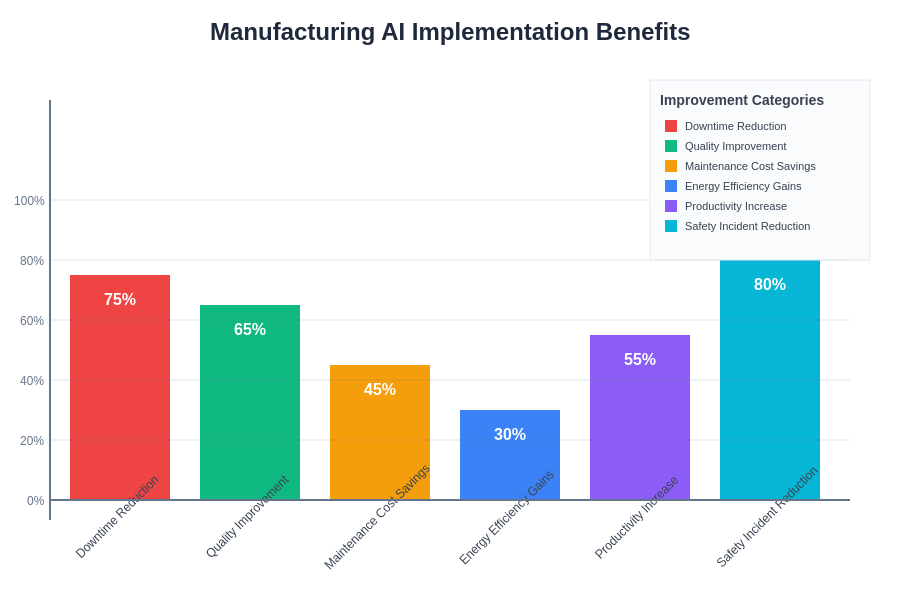

The comprehensive benefits of AI implementation in manufacturing environments extend across multiple operational dimensions, creating value through improved efficiency, reduced costs, enhanced quality, and increased operational flexibility. This multi-faceted impact demonstrates why AI adoption has become a strategic imperative for competitive manufacturing operations.

Predictive Analytics for Supply Chain Integration

Manufacturing AI extends its impact beyond the factory floor to encompass predictive analytics for supply chain optimization, demand forecasting, and inventory management. These applications utilize machine learning algorithms to analyze historical data, market trends, and external factors to predict future demand patterns and optimize supply chain operations accordingly. The integration of predictive analytics into supply chain management enables manufacturers to reduce inventory costs, minimize stockouts, and improve customer satisfaction through more accurate demand fulfillment.

Predictive analytics systems for supply chain management analyze diverse data sources including historical sales data, seasonal patterns, market trends, economic indicators, and external events that may impact demand. These systems can identify complex patterns and relationships that human analysts might overlook and generate accurate forecasts that enable proactive supply chain decisions. The ability to predict demand fluctuations, identify potential supply disruptions, and optimize inventory levels across multiple locations and product lines provides significant competitive advantages in dynamic market environments.

The comprehensive benefits of AI implementation in manufacturing environments extend across multiple operational dimensions, creating value through improved efficiency, reduced costs, enhanced quality, and increased operational flexibility. This multi-faceted impact demonstrates why AI adoption has become a strategic imperative for competitive manufacturing operations.

Leverage advanced research capabilities with Perplexity to stay informed about the latest developments in manufacturing AI and identify emerging opportunities for operational improvement. The rapid pace of technological advancement in this field requires continuous learning and adaptation to maintain competitive advantages.

Energy Optimization and Sustainability

The application of AI to energy management in manufacturing environments represents a critical opportunity for reducing operational costs while supporting sustainability objectives through optimized resource consumption. AI-powered energy management systems analyze energy usage patterns across manufacturing facilities and identify opportunities for efficiency improvements through load balancing, demand response optimization, and predictive energy management strategies. These systems can significantly reduce energy costs while supporting environmental sustainability goals through more efficient resource utilization.

Energy optimization systems utilize machine learning algorithms to model energy consumption patterns and identify correlations between production activities, environmental conditions, and energy usage. These models enable the systems to predict energy demand and automatically adjust equipment operation to minimize consumption while maintaining production requirements. Advanced systems can participate in demand response programs that provide financial incentives for reducing energy consumption during peak demand periods.

The integration of renewable energy sources such as solar and wind power into manufacturing operations creates additional opportunities for AI optimization through predictive management of variable energy supply. AI systems can forecast renewable energy availability and adjust production schedules to maximize utilization of clean energy sources while minimizing reliance on grid power during peak pricing periods.

Worker Safety and Ergonomics Enhancement

AI technologies are increasingly being applied to enhance worker safety and ergonomics in manufacturing environments through continuous monitoring of workplace conditions, worker behavior, and environmental factors that may impact safety and health outcomes. These systems utilize computer vision, wearable sensors, and environmental monitoring equipment to identify potential safety hazards and provide real-time alerts that enable proactive safety interventions before accidents or injuries occur.

Worker safety systems can monitor for compliance with safety protocols such as personal protective equipment usage, safe operating procedures, and restricted area access. Advanced systems can analyze worker movements and postures to identify ergonomic risks that may lead to repetitive strain injuries or other long-term health issues. These systems can provide real-time feedback to workers and supervisors to promote safer working practices and reduce injury rates.

The implementation of AI-powered safety systems requires careful consideration of privacy concerns and worker acceptance to ensure successful deployment and adoption. Effective systems balance comprehensive safety monitoring with respect for worker privacy and autonomy while providing clear benefits that enhance rather than restrict worker effectiveness and satisfaction.

Integration Challenges and Implementation Strategies

The successful implementation of AI technologies in manufacturing environments requires careful planning and execution to address various technical, organizational, and economic challenges that can impact project success. These challenges include data quality and availability issues, integration complexity with existing systems, workforce training and adaptation requirements, and the need for significant capital investment in new technologies and infrastructure.

Data quality represents one of the most critical challenges in AI implementation, as machine learning algorithms require large volumes of high-quality data to develop accurate and reliable models. Manufacturing environments often suffer from data silos, inconsistent data formats, and incomplete historical records that can limit the effectiveness of AI systems. Successful implementations require comprehensive data governance strategies that ensure data quality, consistency, and accessibility across all relevant systems and processes.

Integration with existing manufacturing systems presents additional complexity, particularly in facilities with diverse equipment from multiple vendors and legacy systems that may lack modern connectivity capabilities. Successful integration strategies often require phased implementation approaches that gradually expand AI capabilities while maintaining operational continuity and minimizing disruption to existing processes.

Future Developments and Emerging Technologies

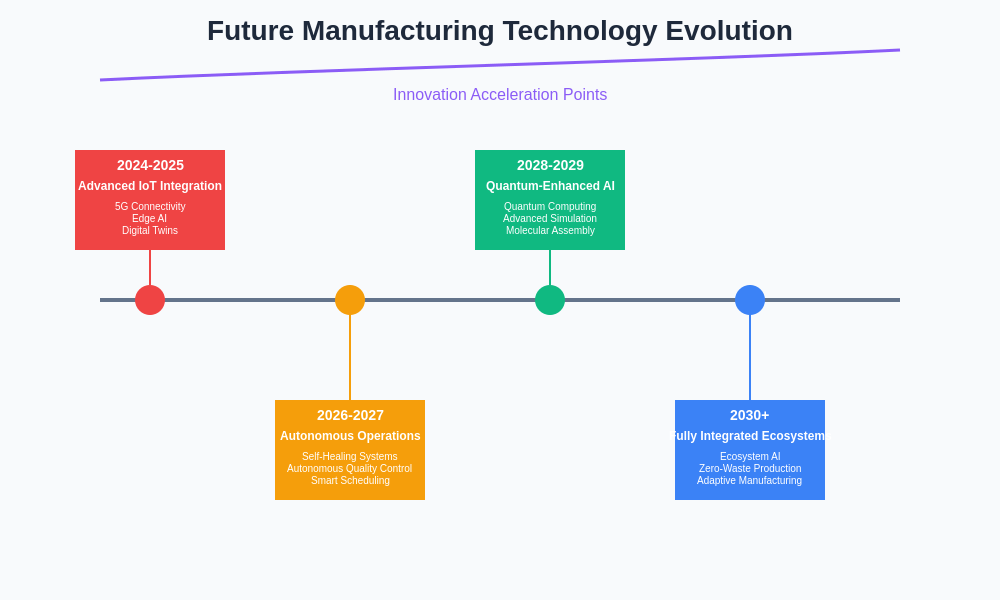

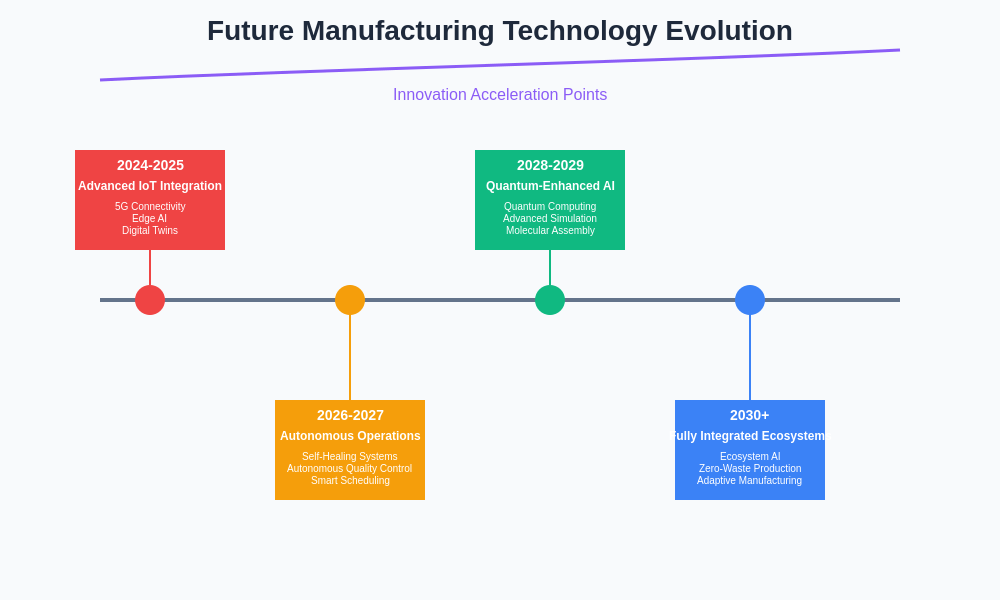

The future of manufacturing AI promises even more sophisticated capabilities through the integration of emerging technologies such as 5G connectivity, edge computing, digital twins, and quantum computing. These technologies will enable more comprehensive data collection, faster processing capabilities, and more sophisticated modeling approaches that further enhance the effectiveness of AI applications in manufacturing environments.

The evolution of manufacturing technology continues to accelerate, with emerging capabilities that promise to further transform industrial operations through enhanced intelligence, connectivity, and automation. This technological progression creates ongoing opportunities for competitive advantage through early adoption and effective implementation of advanced AI capabilities.

5G connectivity will enable real-time data transmission from mobile equipment and remote locations, expanding the scope of AI monitoring and control capabilities throughout manufacturing facilities and supply chains. Edge computing technologies will enable AI processing at the point of data collection, reducing latency and enabling real-time responses to rapidly changing conditions.

Digital twin technologies will create comprehensive virtual models of manufacturing systems that enable simulation and optimization of operations before implementation in physical systems. These virtual environments will enable testing of AI algorithms and optimization strategies without risking disruption to actual production operations.

The evolution of manufacturing technology continues to accelerate, with emerging capabilities that promise to further transform industrial operations through enhanced intelligence, connectivity, and automation. This technological progression creates ongoing opportunities for competitive advantage through early adoption and effective implementation of advanced AI capabilities.

Economic Impact and Return on Investment

The economic benefits of AI implementation in manufacturing extend beyond simple cost savings to encompass revenue enhancement through improved product quality, faster time-to-market for new products, and enhanced customer satisfaction through more reliable delivery performance. Successful AI implementations typically generate return on investment through multiple value streams including reduced maintenance costs, decreased downtime, improved quality yields, optimized energy consumption, and enhanced operational efficiency.

Quantifying the economic impact of AI implementations requires comprehensive measurement of both direct and indirect benefits across extended time periods to capture the full value creation potential of these technologies. Direct benefits such as reduced maintenance costs and decreased downtime are relatively straightforward to measure, while indirect benefits such as improved customer satisfaction and enhanced brand reputation may require more sophisticated measurement approaches.

The investment requirements for AI implementation include both initial capital expenditures for equipment and software as well as ongoing operational costs for system maintenance, data management, and workforce training. Successful implementations require careful financial planning that considers both short-term implementation costs and long-term operational benefits to ensure sustainable value creation.

Regulatory Compliance and Standards

The implementation of AI technologies in manufacturing environments must consider various regulatory requirements and industry standards that govern safety, quality, environmental impact, and data privacy concerns. These requirements vary significantly across industries and geographic regions, requiring careful analysis of applicable regulations and development of compliance strategies that ensure continued adherence throughout the AI system lifecycle.

Quality management standards such as ISO 9001 and industry-specific regulations require documented processes and traceability that must be maintained when implementing AI systems for quality control and process optimization. Safety regulations require comprehensive risk assessments and validation of AI systems that impact worker safety or product safety characteristics.

Data privacy regulations such as GDPR and various national privacy laws require careful consideration of data collection, processing, and storage practices, particularly when AI systems process personal information about workers or customers. Compliance strategies must address data minimization, consent management, and security requirements while maintaining the data access necessary for effective AI operation.

Conclusion and Strategic Recommendations

The transformation of manufacturing through AI-powered predictive maintenance and quality control represents a fundamental shift in how industrial operations are managed and optimized. Organizations that successfully implement these technologies gain significant competitive advantages through improved efficiency, reduced costs, enhanced quality, and greater operational flexibility. However, successful implementation requires careful planning, comprehensive change management, and sustained commitment to continuous improvement and adaptation.

Strategic recommendations for manufacturing organizations considering AI implementation include developing comprehensive data strategies that ensure high-quality information availability, investing in workforce training and development to support AI adoption, implementing phased deployment approaches that minimize risk while demonstrating value, and establishing partnerships with technology providers and research institutions to access specialized expertise and resources.

The future of manufacturing will be increasingly defined by the effective integration of AI technologies that enhance human capabilities rather than replace them. Organizations that recognize this opportunity and invest appropriately in AI capabilities will be well-positioned to thrive in an increasingly competitive and dynamic global marketplace.

Disclaimer

This article is for informational purposes only and does not constitute professional advice regarding AI implementation in manufacturing environments. The information presented is based on current understanding of AI technologies and their applications in industrial settings. Organizations considering AI implementation should conduct thorough assessments of their specific requirements and consult with qualified professionals to develop appropriate implementation strategies. The effectiveness and benefits of AI systems may vary significantly depending on specific operational contexts and implementation approaches.