The modern supply chain landscape has undergone a revolutionary transformation through the integration of artificial intelligence technologies, fundamentally reshaping how businesses approach demand forecasting, inventory management, and logistics optimization. This technological evolution represents more than just an incremental improvement in operational efficiency; it signifies a paradigm shift that enables organizations to achieve unprecedented levels of accuracy in predicting market demands while optimizing complex distribution networks that span global markets and involve countless variables.

Explore the latest AI innovations in supply chain management to stay informed about cutting-edge technologies that are redefining how businesses manage their operations and customer relationships. The convergence of machine learning algorithms, predictive analytics, and real-time data processing has created opportunities for supply chain professionals to make more informed decisions, reduce operational costs, and enhance customer satisfaction through improved service levels and delivery performance.

The Evolution of Supply Chain Intelligence

Traditional supply chain management relied heavily on historical data analysis, intuitive decision-making, and relatively simple forecasting models that often struggled to account for the complex interdependencies and dynamic variables that characterize modern global commerce. The introduction of artificial intelligence into supply chain operations has fundamentally altered this landscape by providing sophisticated analytical capabilities that can process vast amounts of data from multiple sources, identify subtle patterns and correlations, and generate accurate predictions that account for seasonal variations, market trends, economic indicators, and external factors that influence demand patterns.

This transformation has been particularly pronounced in demand forecasting, where AI-powered systems can analyze historical sales data, market trends, weather patterns, economic indicators, social media sentiment, and countless other variables to generate highly accurate predictions about future demand. These advanced forecasting capabilities enable businesses to optimize inventory levels, reduce carrying costs, minimize stockouts, and improve customer satisfaction by ensuring product availability when and where customers need them.

The sophistication of modern AI systems extends beyond simple pattern recognition to encompass complex scenario modeling, risk assessment, and optimization algorithms that can simultaneously consider multiple objectives such as cost minimization, service level maximization, and sustainability goals. This holistic approach to supply chain optimization represents a fundamental shift from reactive management practices to proactive strategic planning that anticipates market changes and positions businesses to respond effectively to emerging opportunities and challenges.

Advanced Demand Forecasting Through Machine Learning

The cornerstone of effective supply chain management lies in accurate demand forecasting, and artificial intelligence has revolutionized this critical function by introducing sophisticated machine learning algorithms that can process and analyze data at scales and speeds that would be impossible for human analysts to achieve. These AI-powered forecasting systems can simultaneously consider hundreds or even thousands of variables that influence demand, including historical sales patterns, seasonal trends, promotional activities, economic indicators, weather conditions, social media sentiment, and competitive dynamics.

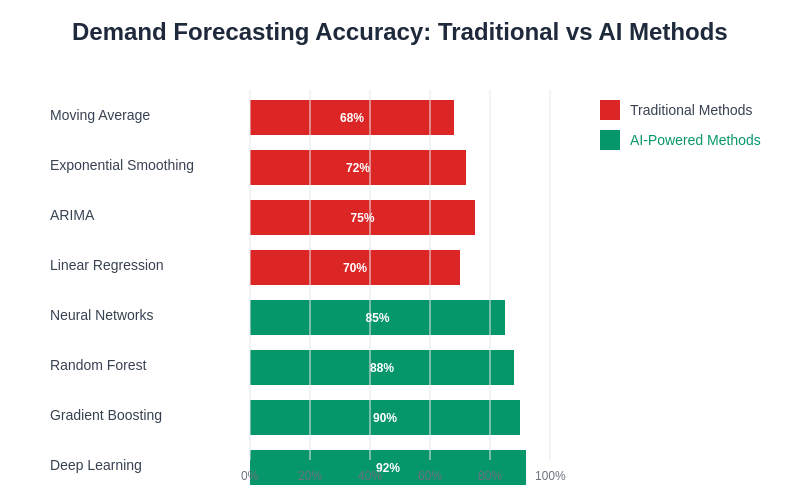

Machine learning models such as neural networks, random forests, and gradient boosting algorithms have demonstrated remarkable capabilities in identifying complex non-linear relationships between various demand drivers that traditional forecasting methods often miss. These algorithms can adapt and learn from new data continuously, improving their accuracy over time and adjusting their predictions based on changing market conditions and consumer behaviors. The result is a dynamic forecasting system that becomes more accurate and reliable as it processes more data and encounters new market situations.

Discover advanced AI capabilities with Claude for comprehensive analysis and strategic planning that can enhance your supply chain optimization initiatives. The integration of multiple AI technologies creates powerful synergies that enable businesses to achieve levels of forecasting accuracy that were previously unattainable through conventional methods.

The implementation of ensemble forecasting approaches, which combine multiple machine learning models to generate consensus predictions, has further enhanced the reliability and robustness of AI-driven demand forecasting systems. These ensemble methods can reduce the impact of individual model biases and limitations while capturing different aspects of demand patterns that might be emphasized by different algorithmic approaches. This comprehensive modeling strategy ensures that forecasting systems remain accurate across diverse product categories, market conditions, and time horizons.

Intelligent Inventory Optimization Strategies

Inventory management represents one of the most complex challenges in supply chain operations, requiring businesses to balance competing objectives such as minimizing carrying costs, avoiding stockouts, optimizing cash flow, and maintaining high service levels. Artificial intelligence has transformed inventory optimization by introducing sophisticated algorithms that can simultaneously consider multiple objectives while accounting for uncertainty in demand, supply lead times, and other critical variables that influence inventory decisions.

AI-powered inventory optimization systems utilize advanced mathematical techniques such as stochastic optimization, dynamic programming, and reinforcement learning to determine optimal inventory policies that adapt to changing conditions and constraints. These systems can analyze historical demand patterns, supplier performance data, lead time variability, and cost structures to generate recommendations for safety stock levels, reorder points, and optimal order quantities that minimize total costs while maintaining target service levels.

The integration of real-time data streams enables these AI systems to continuously monitor inventory levels, demand signals, and supply chain disruptions, allowing them to adjust inventory policies dynamically in response to changing conditions. This real-time optimization capability is particularly valuable in managing seasonal products, promotional items, and products with volatile demand patterns that require frequent adjustments to inventory parameters.

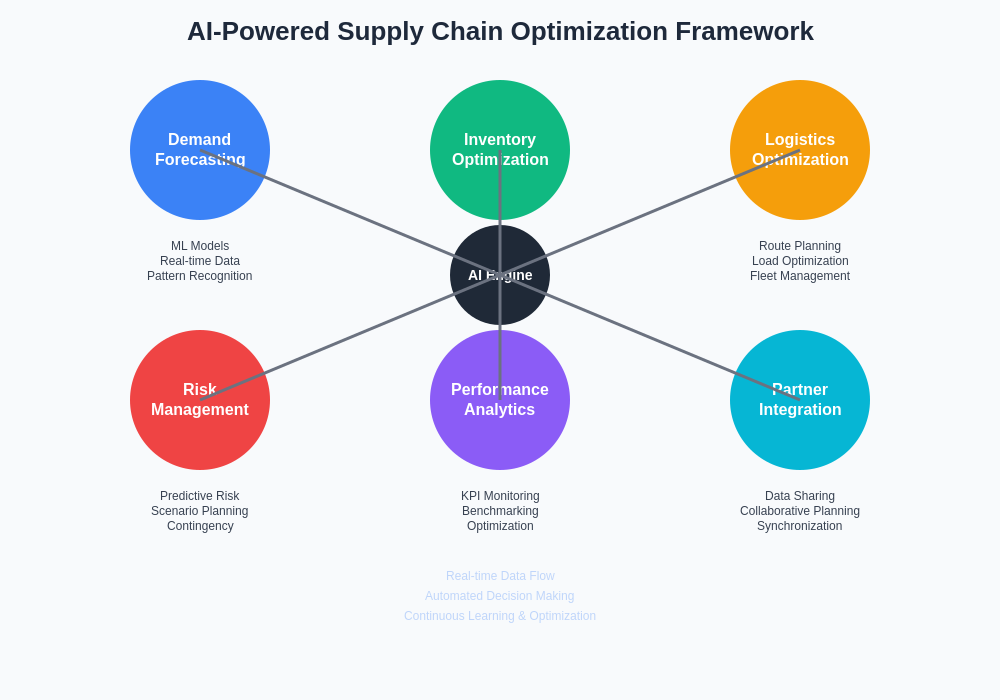

The comprehensive framework for AI-powered supply chain optimization illustrates the interconnected nature of demand forecasting, inventory management, and logistics coordination. This integrated approach ensures that optimization decisions in one area consider the implications for other supply chain functions, creating synergies that enhance overall system performance and efficiency.

Revolutionary Logistics and Distribution Optimization

The logistics and distribution aspects of supply chain management have been fundamentally transformed through the application of artificial intelligence technologies that can optimize complex routing decisions, warehouse operations, and transportation scheduling with unprecedented precision and efficiency. AI-powered logistics optimization systems can simultaneously consider multiple constraints and objectives, including delivery time windows, vehicle capacities, driver availability, fuel costs, traffic conditions, and customer preferences to generate optimal distribution plans that minimize costs while maximizing service quality.

Advanced routing algorithms powered by machine learning can analyze historical traffic patterns, weather conditions, and real-time road conditions to generate dynamic routing plans that adapt to changing circumstances throughout the day. These systems can also optimize loading sequences, delivery schedules, and resource allocation to maximize efficiency and minimize operational costs while ensuring that customer requirements are met consistently.

The implementation of predictive analytics in logistics operations enables businesses to anticipate potential disruptions, such as traffic delays, weather-related challenges, or vehicle breakdowns, and proactively develop contingency plans that minimize their impact on customer service and operational efficiency. This proactive approach to logistics management represents a significant advancement over traditional reactive strategies that could only respond to disruptions after they occurred.

Warehouse automation and optimization have also benefited tremendously from AI integration, with intelligent systems that can optimize storage locations, picking routes, and inventory placement to minimize handling costs and improve order fulfillment speed. These systems can analyze product velocity, seasonal patterns, and order characteristics to determine optimal storage strategies that reduce labor costs and improve operational efficiency.

Integration of IoT and Real-Time Analytics

The Internet of Things revolution has created unprecedented opportunities for supply chain visibility and control by providing real-time data streams from sensors, RFID tags, GPS trackers, and other connected devices throughout the supply chain network. Artificial intelligence systems can process and analyze this continuous flow of real-time data to provide actionable insights and automated responses that enhance operational efficiency and customer service.

Smart sensors embedded in transportation vehicles, warehouse equipment, and product packaging can provide continuous monitoring of temperature, humidity, location, and other critical parameters that affect product quality and delivery performance. AI-powered analytics systems can process this sensor data to detect anomalies, predict equipment failures, and optimize operational parameters to prevent quality issues and minimize downtime.

The integration of real-time analytics with predictive modeling enables supply chain managers to make proactive decisions based on current conditions and future projections, rather than relying solely on historical data and reactive responses. This capability is particularly valuable in managing perishable products, time-sensitive deliveries, and complex multi-modal transportation networks where timing and coordination are critical to success.

Enhance your research capabilities with Perplexity for comprehensive analysis of supply chain trends, market dynamics, and technological developments that impact strategic planning and operational optimization. The combination of multiple AI-powered research and analysis tools creates a comprehensive intelligence platform that supports informed decision-making across all aspects of supply chain management.

Risk Management and Resilience Planning

Supply chain risk management has become increasingly critical in an interconnected global economy where disruptions in one region can have cascading effects throughout entire distribution networks. Artificial intelligence has revolutionized risk management by providing sophisticated analytical capabilities that can identify potential vulnerabilities, assess risk probabilities, and develop mitigation strategies that enhance supply chain resilience while maintaining operational efficiency.

AI-powered risk assessment systems can analyze multiple data sources, including news feeds, weather forecasts, economic indicators, geopolitical developments, and supplier financial health, to identify potential risks before they materialize into actual disruptions. These systems can quantify risk probabilities and potential impacts, enabling supply chain managers to prioritize mitigation efforts and allocate resources effectively to address the most significant threats.

The development of scenario modeling and simulation capabilities allows businesses to test different risk mitigation strategies and evaluate their effectiveness under various conditions. These simulation tools can help organizations develop robust contingency plans that can be activated quickly when disruptions occur, minimizing their impact on customer service and operational performance.

Machine learning algorithms can also identify patterns in historical disruption data to predict which suppliers, routes, or facilities are most likely to experience problems, enabling proactive measures such as supplier diversification, alternative routing plans, and strategic inventory positioning to reduce vulnerability to specific risk factors.

Sustainability and Environmental Optimization

Environmental sustainability has become a critical consideration in supply chain management, driven by regulatory requirements, customer expectations, and corporate social responsibility initiatives. Artificial intelligence is playing an increasingly important role in helping businesses optimize their supply chain operations to reduce environmental impact while maintaining cost effectiveness and service quality.

AI-powered carbon footprint analysis systems can evaluate the environmental impact of different supply chain configurations, transportation modes, and operational strategies, enabling businesses to make informed decisions that balance sustainability goals with operational requirements. These systems can analyze factors such as fuel consumption, emissions, packaging waste, and energy usage to identify opportunities for environmental improvement.

Optimization algorithms can incorporate sustainability metrics alongside traditional cost and service objectives, generating solutions that achieve multiple goals simultaneously. For example, route optimization systems can minimize both transportation costs and carbon emissions, while inventory optimization models can consider both carrying costs and waste reduction objectives.

The substantial improvements in forecasting accuracy achieved through AI implementation demonstrate the tangible benefits of adopting advanced analytics technologies. Organizations utilizing machine learning-based forecasting systems consistently achieve superior performance across multiple accuracy metrics compared to traditional statistical methods.

Supply Chain Visibility and Transparency

Modern consumers and business customers increasingly demand transparency and visibility into supply chain operations, driving the need for comprehensive tracking and reporting capabilities that can provide real-time information about product origins, manufacturing processes, and delivery status. Artificial intelligence enables unprecedented levels of supply chain visibility by integrating data from multiple sources and providing intuitive dashboards and reporting tools that make complex information accessible to stakeholders throughout the organization.

Blockchain integration with AI analytics creates immutable records of supply chain transactions and movements, enhancing traceability and enabling rapid response to quality issues or recalls. These systems can track products from raw material sourcing through final delivery, providing complete visibility into the supply chain journey and enabling quick identification of any issues that may arise.

Predictive analytics can also enhance visibility by providing forward-looking insights into potential supply chain performance, enabling proactive communication with customers about delivery schedules, potential delays, and service levels. This predictive visibility helps build customer confidence and enables better coordination between supply chain partners.

Collaborative Planning and Partner Integration

The complexity of modern supply chains requires sophisticated coordination and collaboration between multiple partners, including suppliers, manufacturers, distributors, and logistics providers. Artificial intelligence facilitates this collaboration by providing platforms and tools that enable seamless information sharing, coordinated planning, and synchronized execution across the entire supply chain network.

AI-powered collaborative planning systems can integrate data and forecasts from multiple partners to generate consensus demand plans that optimize the entire network rather than individual components. These systems can identify conflicts and inconsistencies in partner plans and suggest adjustments that improve overall network performance while meeting individual partner objectives.

Machine learning algorithms can analyze partner performance data to identify best practices, optimize relationship management, and predict potential issues that may affect collaborative efforts. This analysis enables supply chain managers to make informed decisions about partner selection, contract terms, and performance management strategies.

Implementation Strategies and Change Management

Successfully implementing AI-powered supply chain optimization requires careful planning, change management, and organizational commitment to technology adoption and process improvement. Organizations must develop comprehensive implementation strategies that address technology infrastructure, data quality, skill development, and cultural change management to realize the full benefits of AI integration.

Data quality and accessibility represent critical foundation elements for successful AI implementation, requiring organizations to invest in data governance, integration platforms, and quality management processes that ensure AI systems have access to accurate, complete, and timely information. This data infrastructure investment often represents a significant upfront cost but is essential for achieving the performance improvements that AI technologies can deliver.

Skill development and training programs are essential for building organizational capabilities in AI technology management, analytics, and strategic planning. These programs should address both technical skills and strategic thinking capabilities that enable employees to effectively leverage AI insights in their decision-making processes.

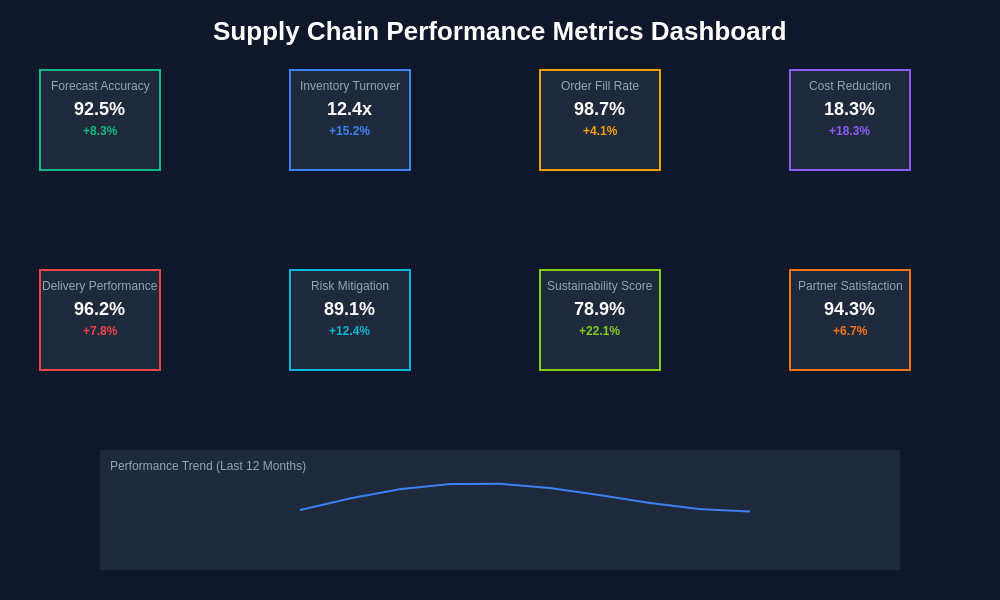

Comprehensive performance monitoring and measurement systems enable organizations to track the impact of AI implementation and identify opportunities for continuous improvement. These dashboards provide real-time visibility into key performance indicators that demonstrate the value of AI investments and guide future optimization efforts.

Future Trends and Emerging Technologies

The future of supply chain AI promises even more sophisticated capabilities as emerging technologies such as quantum computing, advanced robotics, and next-generation machine learning algorithms continue to evolve. These technological advances will enable new applications and capabilities that further enhance supply chain performance and create new opportunities for competitive advantage.

Quantum computing applications in supply chain optimization could revolutionize complex optimization problems by enabling the simultaneous evaluation of vastly more variables and constraints than current classical computing systems can handle. This capability could lead to breakthrough improvements in network optimization, routing efficiency, and resource allocation across complex global supply chains.

Advanced robotics integration with AI decision-making systems will create autonomous supply chain operations that can adapt and respond to changing conditions without human intervention. These systems will be capable of self-optimization, predictive maintenance, and continuous improvement that enhances efficiency and reduces operational costs.

The continued evolution of machine learning algorithms and artificial intelligence capabilities will enable even more sophisticated demand forecasting, risk management, and optimization capabilities that push the boundaries of what is possible in supply chain management. These advances will continue to create new opportunities for businesses to improve their competitive position through superior supply chain performance.

The integration of artificial intelligence into supply chain management represents a fundamental transformation that is reshaping how businesses operate in the global marketplace. Organizations that successfully embrace these technologies and develop the capabilities to leverage AI insights effectively will be well-positioned to achieve superior performance, enhanced customer satisfaction, and sustainable competitive advantages in an increasingly complex and dynamic business environment.

Disclaimer

This article is for informational purposes only and does not constitute professional advice. The views expressed are based on current understanding of AI technologies and their applications in supply chain management. Readers should conduct their own research and consult with qualified professionals when making decisions about supply chain technology investments and implementation strategies. The effectiveness of AI solutions may vary depending on specific business requirements, data quality, and implementation approaches.